10 月 . 22, 2024 06:56 Back to list

Durable Stainless Steel Butterfly Valve for Optimal Flow Control and Performance

Stainless Steel Butterfly Valve A Comprehensive Overview

Butterfly valves are critical components in various industrial applications, designed primarily for regulating or isolating flow in pipelines. Among the various materials used to manufacture these valves, stainless steel has emerged as a popular choice due to its numerous advantages. This article provides a comprehensive overview of stainless steel butterfly valves, discussing their design, advantages, applications, and maintenance.

Design Features

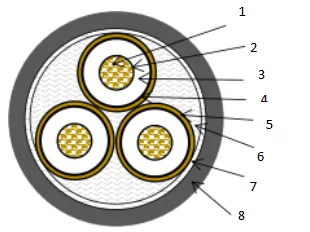

A stainless steel butterfly valve consists of a circular disc that rotates around a central axis, allowing for smooth flow control. When the valve is open, the disc aligns with the pipeline, permitting the flow of fluids; when closed, the disc is perpendicular to the flow, effectively blocking it. The body of the valve is made from stainless steel, a material known for its corrosion resistance and mechanical strength.

Stainless steel butterfly valves are typically categorized into two main types resilient seated and metal seated. Resilient seated valves feature a soft sealing material, which provides excellent leak-tightness, making them suitable for applications where precision is essential. Metal seated valves, on the other hand, are designed to withstand high temperatures and pressures, ideal for more severe service conditions.

Advantages of Stainless Steel Butterfly Valves

1. Corrosion Resistance One of the most significant benefits of stainless steel butterfly valves is their resistance to corrosion. This property allows them to perform well in various environments, including chemical processing, sewage treatment, and food and beverage applications.

2. Durability Stainless steel is a robust material that can withstand significant wear and tear. This durability translates into a longer lifespan for the valves, reducing the need for frequent replacements and minimizing downtime.

stainless steel butterfly valve

3. Cost-Effectiveness Although the initial cost of stainless steel butterfly valves may be higher than that of valves made from other materials, their longevity and reduced maintenance needs make them a cost-effective choice in the long run.

4. Versatility These valves are suitable for a wide range of applications, including water treatment, HVAC systems, and even pharmaceuticals. Their ability to handle various fluids, including gases and slurries, enhances their versatility in different industries.

5. Ease of Operation The design of butterfly valves allows them to be operated quickly and easily. They can be actuated using manual lever systems or automated actuators, providing flexibility in operation.

Applications

Stainless steel butterfly valves are utilized across various sectors due to their reliability and performance. In the water treatment industry, they regulate the flow of water and can isolate sections of piping for maintenance. In the food and beverage industry, their corrosion resistance is vital for maintaining hygiene and safety standards. Additionally, they are frequently used in HVAC systems for controlling airflow and in chemical processing plants for handling corrosive substances.

Maintenance

While stainless steel butterfly valves are low maintenance due to their durable construction, regular inspections are essential to ensure optimal performance. Key maintenance practices include checking for signs of wear on the sealing surfaces, ensuring proper operation of the actuator, and confirming that the valve fully opens and closes without obstruction.

In conclusion, stainless steel butterfly valves are essential components in various industrial applications. Their unique combination of durability, corrosion resistance, and versatility makes them an excellent choice for flow control in diverse environments. Understanding their design, advantages, and maintenance needs is crucial for industries relying on reliable valve solutions. As technology advances, we can expect further innovations in the design and application of these vital components, ensuring they continue to meet the evolving demands of modern industry.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024