10 月 . 21, 2024 16:57 Back to list

Stainless Steel Butterfly Valve for Reliable Flow Control in Industrial Applications

Stainless Steel Butterfly Valve An Essential Component for Fluid Control

The stainless steel butterfly valve is a crucial component in various industrial applications, renowned for its efficiency, durability, and versatility. This type of valve is primarily used to regulate flow within a pipeline, offering a simple yet effective mechanism for controlling the passage of liquids and gases. As industries continue to evolve, the demand for high-quality materials and innovative designs has led to the widespread adoption of stainless steel butterfly valves.

Construction and Design Features

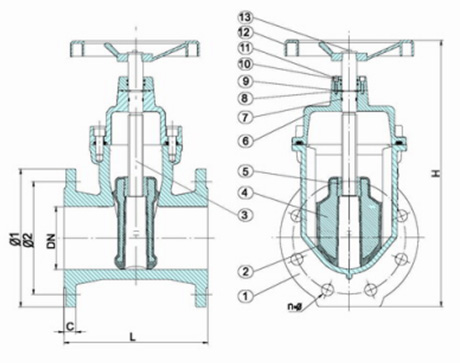

A typical stainless steel butterfly valve consists of a circular disc or plate that pivots around a centrally located shaft. When the valve is closed, the disc is perpendicular to the flow, effectively blocking the passage. Conversely, when the valve is opened, the disc rotates to align with the flow, allowing for unobstructed movement of the fluid. The simplicity of this design makes it highly efficient, as the valve can be operated quickly and requires minimal space within the pipeline.

Stainless steel, known for its corrosion resistance and strength, is the preferred material for butterfly valves in many applications. The use of stainless steel helps to ensure longevity and optimal performance, especially in harsh environments where exposure to aggressive chemicals or extreme temperatures is a concern. Additionally, the smooth surface of stainless steel minimizes friction, which contributes to the ease of operation and helps reduce wear and tear over time.

Applications of Stainless Steel Butterfly Valves

Stainless steel butterfly valves are extensively used across various industries, including water treatment, chemical processing, food and beverage, oil and gas, and power generation. In water treatment facilities, these valves help manage the flow of water through different stages of processing, ensuring efficient distribution and effective management of resources. In the chemical industry, their ability to withstand corrosive substances makes them ideal for use in handling acids, bases, and solvents.

stainless steel butterfly valve

In the food and beverage sector, hygiene and safety are paramount. Stainless steel butterfly valves are designed to meet sanitary standards, ensuring that there is no contamination during the processing of consumables. Their easy cleaning capabilities contribute to compliance with stringent safety regulations, making them a reliable choice for food manufacturing.

In oil and gas operations, these valves play a vital role in controlling the flow of both crude oil and natural gas, helping to maintain operational safety and efficiency. In power plants, they regulate steam and water flow, contributing to the overall effectiveness of power generation systems.

Advantages of Stainless Steel Butterfly Valves

The advantages of stainless steel butterfly valves are numerous. Firstly, their lightweight and compact design allow for easy installation and maintenance, reducing labor costs and downtime. Secondly, the quick operation of the valves—often requiring only a quarter turn—enables rapid response to changing flow conditions, which is critical in many industrial processes.

Moreover, the versatility of these valves is another major benefit. They can be utilized in various systems, including those requiring throttling control, on-off applications, or even in high-pressure situations. Their adaptability to different pipeline sizes and configurations adds to their appeal in the market.

Conclusion

In conclusion, the stainless steel butterfly valve is an indispensable element in modern fluid control systems. Its robust construction, combined with the benefits of stainless steel, ensures reliable performance across a wide range of industries. As industries demand greater efficiency and sustainability, the role of stainless steel butterfly valves will continue to grow, solidifying their status as a key component in fluid management and control. Whether in wastewater treatment, food processing, or energy production, these valves stand out for their functionality and reliability, making them a preferred choice for engineers and operators alike.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024