2 月 . 15, 2025 22:36 Back to list

stainless steel ball check valve

The stainless steel ball check valve stands as a crucial component in various industrial applications, sought after for its reliability and durability. Known particularly for its ability to facilitate unidirectional flow, it prevents backflow and ensures that systems function at optimal efficiency. Understanding the significance and intricacies of this component can distinctly benefit industries ranging from oil and gas to pharmaceuticals.

From an expertise perspective, it is crucial to comprehend the valve's design considerations. The ball mechanism in stainless steel check valves ensures a tight seal which is pivotal in minimizing leaks. The spherical design of the ball is critical – it must align perfectly with the valve seat to achieve an effective seal when backflow pressure occurs. Understandably, precision in design and manufacturing is essential, which is why collaboration with reputable manufacturers can make a significant difference. Adapting to advanced technology in valve systems can further enhance operational efficiency. Modern innovations have introduced automated stainless steel ball check valves that integrate sensors and monitoring systems. These advancements provide real-time data analytics, facilitating predictive maintenance strategies that can preempt potential faults, thereby reducing downtime and operational costs. To solidify authority in this domain, manufacturers should foster transparency in their material sourcing and production processes. By opting for environmentally sustainable practices and ensuring ethical labor conditions, companies not only enhance their standing but also contribute positively to global ecological efforts. In conclusion, the stainless steel ball check valve is a pivotal asset across various industries. Its inherent qualities of durability, corrosion resistance, and the ability to withstand extreme conditions make it indispensable. However, making informed decisions based on thorough research, reliable guarantees, and adopting innovative technologies is vital in leveraging these valves to their fullest potential. Investing in high-quality stainless steel ball check valves not only ensures operational excellence but also aligns with long-term business sustainability goals.

From an expertise perspective, it is crucial to comprehend the valve's design considerations. The ball mechanism in stainless steel check valves ensures a tight seal which is pivotal in minimizing leaks. The spherical design of the ball is critical – it must align perfectly with the valve seat to achieve an effective seal when backflow pressure occurs. Understandably, precision in design and manufacturing is essential, which is why collaboration with reputable manufacturers can make a significant difference. Adapting to advanced technology in valve systems can further enhance operational efficiency. Modern innovations have introduced automated stainless steel ball check valves that integrate sensors and monitoring systems. These advancements provide real-time data analytics, facilitating predictive maintenance strategies that can preempt potential faults, thereby reducing downtime and operational costs. To solidify authority in this domain, manufacturers should foster transparency in their material sourcing and production processes. By opting for environmentally sustainable practices and ensuring ethical labor conditions, companies not only enhance their standing but also contribute positively to global ecological efforts. In conclusion, the stainless steel ball check valve is a pivotal asset across various industries. Its inherent qualities of durability, corrosion resistance, and the ability to withstand extreme conditions make it indispensable. However, making informed decisions based on thorough research, reliable guarantees, and adopting innovative technologies is vital in leveraging these valves to their fullest potential. Investing in high-quality stainless steel ball check valves not only ensures operational excellence but also aligns with long-term business sustainability goals.

Share

Latest news

-

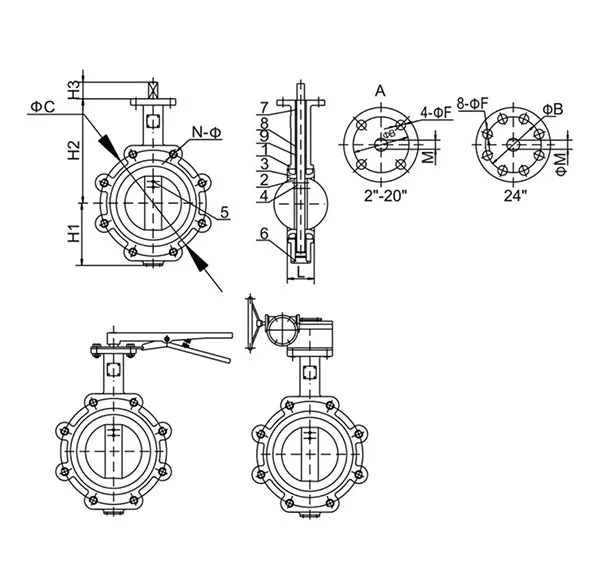

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024