12 月 . 03, 2024 16:17 Back to list

SS Flange Type Ball Valve Options for Various Applications and Industries

Understanding SS Ball Valve Flange Type

In industrial applications, the choice of valves can significantly influence the efficiency, safety, and functionality of a system. Among the various types of valves available, the stainless steel (SS) ball valve, specifically the flange type, has gained prominence due to its durability, versatility, and performance characteristics. This article explores the fundamental aspects of SS ball valves, particularly the flange type, and their applications in various industries.

What is a SS Ball Valve?

A ball valve is a type of quarter-turn valve that uses a spherical disc (the ball) to control the flow of fluid. It operates by rotating the ball within the valve body — when the ball's hole is in line with the flow, the valve is open, and when it is perpendicular, the valve is closed. Stainless steel is commonly used in ball valves due to its resistance to corrosion, high strength, and suitability for high-pressure applications. The SS ball valve flange type refers to valves that have flanged ends, facilitating secure mounting to pipelines.

Key Features of SS Ball Valve Flange Type

1. Durability Stainless steel offers superior resistance to corrosion and scaling, making it suitable for various fluid types, including corrosive substances. This durability extends the lifespan of the valve, leading to lower maintenance costs and reduced downtime in operations.

2. High Temperature and Pressure Resistance SS ball valves can endure extreme temperatures and pressures, making them ideal for demanding industrial environments, such as oil and gas extraction, chemical processing, and water treatment.

3. Flanged Connections The flange design provides a robust connection to piping systems, facilitating ease of installation and removal. Flanged ends allow for the secure assembly of the valve with other components, ensuring minimal leakage and enhancing system integrity.

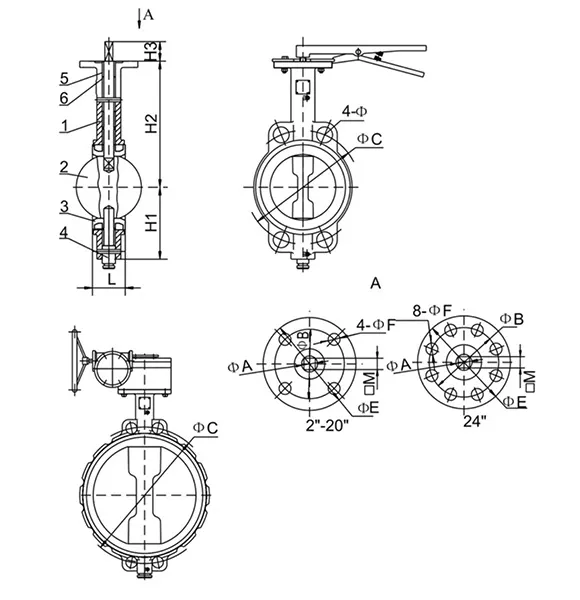

ss ball valve flange type

4. Flow Control The design of ball valves allows for quick and efficient flow control. Their quarter-turn operation enables rapid opening and closing, which is crucial in emergency situations or where quick flow adjustments are required.

5. Versatile Applications SS ball valves with flanged connections are utilized across various sectors, including oil and gas, petrochemicals, food and beverage processing, pharmaceuticals, and water distribution. Their adaptability makes them an essential choice in many fluid handling systems.

Advantages of Flanged Type Ball Valves

- Ease of Maintenance The design of flanged ball valves allows for straightforward access during maintenance and inspections, ensuring that the system can be serviced without extensive disassembly of connected piping. - Sealing Performance Flanged ball valves typically employ high-quality sealing materials, which enhance their performance in preventing leaks, a critical factor in maintaining system safety and efficiency.

- Standardization Flanged ball valves adhere to various industry standards (such as ANSI, API, or ISO), facilitating compatibility with existing piping infrastructure and components. This standardization also helps in meeting regulatory requirements.

Conclusion

The SS ball valve flange type is integral to modern industrial systems, providing reliable control and sealing capabilities in various dynamic environments. Its robust construction, coupled with the advantages of flanged connections, makes it an ideal choice for many applications. As industries continue to seek efficient and durable flow control solutions, the demand for stainless steel ball valves will likely persist, underscoring their importance in the world of engineering and fluid management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024