9 月 . 08, 2024 03:02 Back to list

High-Quality SS Ball Valve - Durable and Reliable Flow Control Solutions

Understanding SS Ball Valves A Comprehensive Overview

Stainless steel (SS) ball valves are crucial components in various industrial applications, known for their reliability and durability. These valves are mainly used to control the flow of liquids and gases in pipelines, providing a tight seal and allowing for quick shut-off capabilities.

What is a Ball Valve?

A ball valve is a type of quarter-turn valve that utilizes a spherical closure element, or ball, with a hole through its center. When the ball is rotated a quarter turn, the hole aligns with the flow direction, allowing fluid to pass through. Conversely, when the ball is rotated 90 degrees, the hole is perpendicular to the flow, effectively blocking it. This simple yet effective design makes ball valves an excellent choice for on/off control.

Why Stainless Steel?

Stainless steel is favored for manufacturing ball valves due to its corrosion resistance, strength, and ability to withstand high temperatures. The material is particularly beneficial in industries where fluid properties can be aggressive, such as in chemical, oil and gas, and water treatment applications. The superior mechanical properties of stainless steel provide these valves with extended service life, reducing maintenance costs and downtime.

Types of SS Ball Valves

There are different types of stainless steel ball valves available, catering to various needs

1. Two-Piece Ball Valves Comprising two body parts, this design allows for easy repair and maintenance. It provides a robust solution for applications that may require regular servicing.

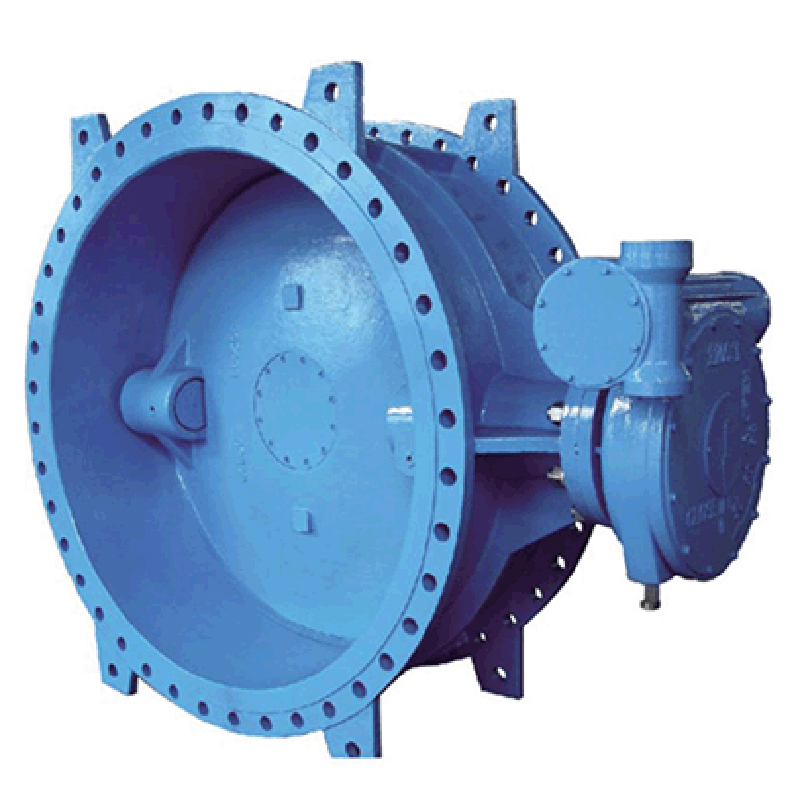

ss ball valve

2. Three-Piece Ball Valves Featuring three body parts, this design ensures greater flexibility. It can be easily disassembled without removing the valve from the pipeline, making it ideal for maintenance purposes.

3. Full Port vs. Reduced Port Full port ball valves have a larger diameter than the pipeline, allowing for unrestricted flow. Reduced port valves have a smaller diameter, leading to a slight pressure drop in some applications.

Advantages of SS Ball Valves

The advantages of using stainless steel ball valves are manifold. They provide a tight seal, minimizing leakages and ensuring safety in operations. Their design allows for quick operation, which is essential in processes where flow control is critical. Additionally, stainless steel ball valves are versatile, available in various sizes and configurations to suit different applications.

Applications

SS ball valves find applications across numerous sectors, including oil and gas, pharmaceuticals, food and beverage, HVAC systems, and water treatment facilities. Their reliability and high performance make them a preferred choice for handling a wide range of fluids.

Conclusion

In summary, stainless steel ball valves play a pivotal role in fluid control across various industries. Their robust construction, reliability, and efficient design make them indispensable in modern engineering applications. Understanding their functionality and advantages can aid professionals in making informed decisions when selecting the right valve for their needs. With the growing demand for safety and efficiency in fluid management, SS ball valves will continue to be a vital asset in the industrial sector.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024