10 月 . 04, 2024 01:12 Back to list

socket and resilient seat gate valve

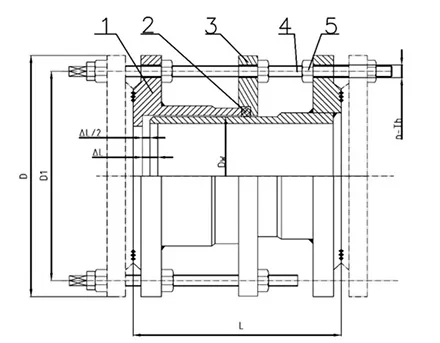

Socket and Resilient Seat Gate Valve A Comprehensive Overview

Socket and resilient seat gate valves are essential components widely used in various industrial applications, particularly in water distribution, sewer systems, and other fluid control processes. Their design and functionality offer numerous advantages, making them a popular choice among engineers and facility managers.

A gate valve primarily serves to start or stop the flow of fluids. Unlike other valve types, such as ball or butterfly valves, the gate valve is designed to be fully open or fully closed, providing minimal resistance to flow when fully open. The socket design enhances the valve's installation process, allowing for easier and more efficient connections to pipe systems without the need for complex fittings. This feature not only simplifies installation but also reduces potential leak points, increasing the reliability of the system.

The resilient seat, often made from elastomeric materials such as rubber, plays a crucial role in the performance of the gate valve. This type of seating provides a tight seal when the valve is closed, minimizing fluid leakage, which is vital for maintaining system integrity. The resilient material also accommodates minor misalignments and thermal expansion, making the valve more forgiving in fluctuating operational conditions.

socket and resilient seat gate valve

One of the significant benefits of using socket and resilient seat gate valves is their durability

. The materials used in the fabrication of these valves are engineered to withstand harsh operational environments, including corrosive fluids and extreme temperatures. Additionally, the robust design of the gate mechanism reduces wear and tear, ensuring a longer service life compared to other valve types.Maintenance of socket and resilient seat gate valves is relatively straightforward. As these valves do not feature intricate moving parts, the likelihood of mechanical failure is reduced. Regular inspection for wear on the resilient seat and the gate itself is usually sufficient to maintain their functionality. Should maintenance be required, the valve design typically allows for easy replacement of parts without needing to remove the entire valve from the pipeline.

In conclusion, socket and resilient seat gate valves offer a combination of durability, ease of installation, and reliable performance, making them a preferred choice for many fluid control applications. Their robust design and functional efficiency ensure that industries can maintain consistent operations while minimizing downtime related to valve failure or maintenance. As industries continue to seek reliable solutions for fluid management, the relevance and application of these valves will undoubtedly continue to grow.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024