9 月 . 15, 2024 20:14 Back to list

High-Performance Slurry Knife Gate Valve for Efficient Flow Control

Understanding Slurry Knife Gate Valves A Comprehensive Overview

Slurry knife gate valves are specialized valves designed to control the flow of slurry—a mixture of solid particles and liquid—commonly found in industries such as mining, wastewater treatment, and pulp and paper. These valves play a crucial role in managing the transportation of abrasive and viscous materials while minimizing wear and ensuring efficient operation.

Design and Functionality

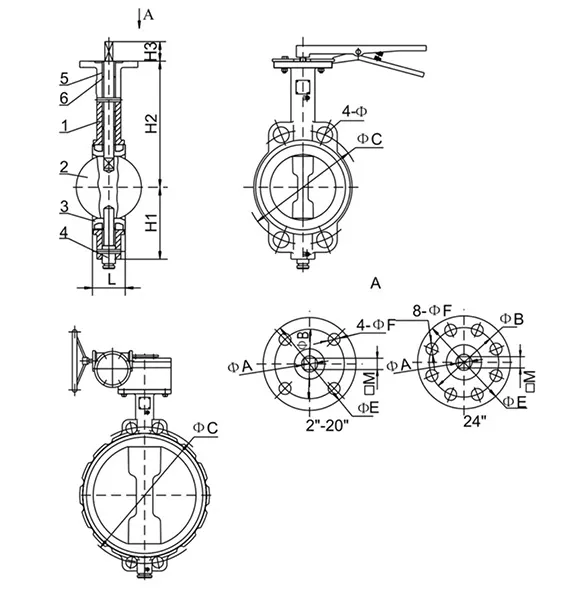

The primary function of a knife gate valve is to provide a reliable shutoff for flowing materials, particularly slurries. Unlike traditional gate valves, which can become clogged with solid particles, knife gate valves feature a sharp-edged blade that can slice through dense mixtures. This design allows the valve to effectively isolate the flow while preventing blockages, making it ideal for applications involving thick slurries.

Most knife gate valves are constructed from robust materials such as cast iron, stainless steel, or specialized alloys, which offer durability against abrasive materials. The blade’s design not only ensures a tight seal when closed but also allows for the efficient passage of fluids when open.

Applications in Various Industries

In the mining industry, slurry knife gate valves are used in the transportation of ore slurry from the processing plant to the tailings pond. Their ability to handle high solid content and maintain flow control is vital for operational efficiency. Additionally, in wastewater treatment, these valves manage the flow of sludge and serve in various treatment processes where solids are prevalent.

slurry knife gate valve

Pulp and paper industries also benefit from slurry knife gate valves in controlling the flow of pulp mixtures during various stages of production

. By offering reliable shutoff capabilities, these valves enhance operational safety and improve the overall quality of the final product.Advantages Over Traditional Valves

One of the significant advantages of slurry knife gate valves is their design that minimizes the likelihood of clogging, a common issue with conventional valves. The cleanout feature in many designs allows for easy maintenance and ensures that operators can quickly address blockages without extensive downtime.

Moreover, the ability to maintain a tight seal and accommodate varying pressures makes these valves highly versatile in various applications. The reduced maintenance requirements, coupled with their long service life, contribute to lower operational costs in the long run.

Conclusion

In conclusion, slurry knife gate valves are essential components in managing the flow of slurry in several industries, offering reliable performance, reduced maintenance, and enhanced operational efficiency. As industries continue to evolve, the demand for innovative valve solutions like the slurry knife gate valve remains crucial for optimizing processes and ensuring safety in handling challenging materials. With their robust design and functionality, these valves are poised to play a pivotal role in future industrial applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024