9 月 . 04, 2024 16:42 Back to list

single plate check valve

Understanding Single Plate Check Valves Functionality and Applications

Single plate check valves, often referred to as flap valves, are critical components in various fluid systems. Ingeniously designed to allow flow in one direction while preventing backflow, these valves are essential in many industrial applications, including water treatment, oil and gas, and chemical manufacturing.

Design and Mechanism

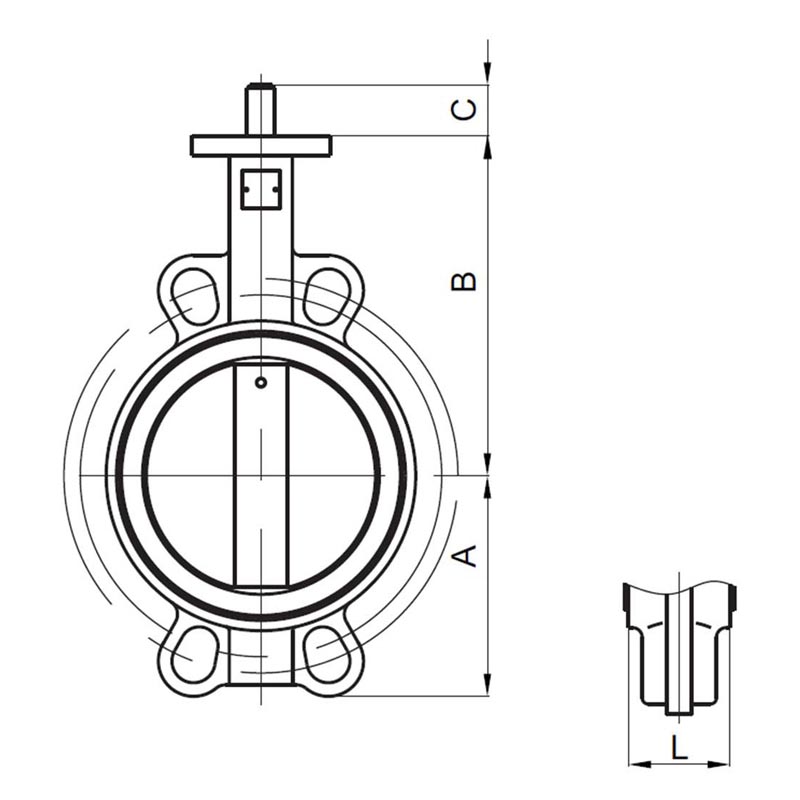

The single plate check valve consists of a flat disc or plate that pivots around a hinge. Its design is relatively simple yet effective. When fluid flows in the intended direction, the pressure forces the plate to open, allowing the fluid to pass through. Conversely, when the flow attempts to reverse, the pressure from the backflow forces the plate to close against its seat, creating a tight seal that prevents any fluid from flowing back. This one-way operation is what characterizes the valve and is vital for preventing contamination and ensuring system efficiency.

One of the primary advantages of a single plate check valve is its compact design. Compared to traditional swing or lift check valves, the single plate variant occupies less space and is lighter, making it easier to install in various locations within a piping system.

Key Advantages

1. Compact and Lightweight The streamlined design allows for easy integration into existing systems without necessitating significant pipe modifications.

single plate check valve

3. Versatile Applications These valves can be utilized in various environments, including high-pressure settings and corrosive media. Their adaptability makes them suitable for water supply systems, HVAC applications, and numerous industrial processes.

4. Reduced Turbulence The flat plate design minimizes the obstruction of fluid flow, reducing turbulence and improving energy efficiency within the system.

5. Simple Maintenance Maintenance requirements for single plate check valves are comparatively low, given their straightforward design. Routine checks can help ensure optimal performance without the need for frequent part replacements.

Applications

Single plate check valves are utilized in various industries due to their reliability and efficiency. In water treatment facilities, they help prevent backflow, ensuring that treated water remains uncontaminated. In the oil and gas sector, they protect pipelines from pressure surges and reverse flow, which could lead to spillage and catastrophic failures. Furthermore, in chemical processing, these valves play a crucial role in maintaining the integrity of the system by safeguarding against unwanted backflow that could mix incompatible substances.

Conclusion

In summary, single plate check valves are indispensable components in modern fluid systems. Their unique design, coupled with their operational efficiency, makes them vital for a wide array of applications across multiple industries. By preventing backflow, they not only enhance system reliability but also contribute to safety and efficiency. As industries continue to evolve and demand higher levels of performance, the importance of effective flow control solutions like the single plate check valve will undoubtedly grow. Understanding their function and advantages is crucial for anyone involved in system design, maintenance, or operation.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024