1 月 . 15, 2025 09:59 Back to list

Portable Cord

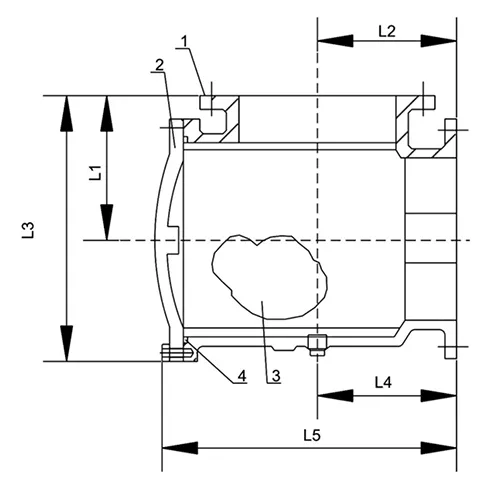

Silent check valves are an essential component in numerous industrial and residential applications, lauded for their efficiency and reliability in controlling fluid systems. Crafted for precision, these valves ensure a unidirectional flow and prevent backflow, a common challenge in plumbing and piping systems. Their importance is unparalleled, thanks to their unique design that mitigates noise, reduces wear and tear, and thus enhances system longevity.

Trustworthiness in silent check valves is demonstrated through their robust construction and the manufacturer's adherence to global industry standards. Customers can trust these valves for their reliability over time due to rigorous testing and quality assurance processes during production. Moreover, leading manufacturers provide extensive warranties and service support, which further boosts consumer confidence in the performance and longevity of the valves. In considering the environmental impact, silent check valves contribute to energy efficiency. By ensuring a smooth and quiet operation, they minimize the energy losses typically observed in chattering valves, making them an eco-friendly choice for sustainable fluid management systems. In summary, the right selection and application of silent check valves are critical for ensuring both system longevity and user satisfaction. They combine the benefits of noise reduction, reliability, and cost-effectiveness, making them indispensable in both industrial and residential environments. As more industries recognize the multifaceted advantages of silent check valves, their adoption is set to rise, affirming their status as a key component in modern piping systems. Remember, a sound choice in fluid control today warrants the assurance of seamless operations tomorrow.

Trustworthiness in silent check valves is demonstrated through their robust construction and the manufacturer's adherence to global industry standards. Customers can trust these valves for their reliability over time due to rigorous testing and quality assurance processes during production. Moreover, leading manufacturers provide extensive warranties and service support, which further boosts consumer confidence in the performance and longevity of the valves. In considering the environmental impact, silent check valves contribute to energy efficiency. By ensuring a smooth and quiet operation, they minimize the energy losses typically observed in chattering valves, making them an eco-friendly choice for sustainable fluid management systems. In summary, the right selection and application of silent check valves are critical for ensuring both system longevity and user satisfaction. They combine the benefits of noise reduction, reliability, and cost-effectiveness, making them indispensable in both industrial and residential environments. As more industries recognize the multifaceted advantages of silent check valves, their adoption is set to rise, affirming their status as a key component in modern piping systems. Remember, a sound choice in fluid control today warrants the assurance of seamless operations tomorrow.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024