9 月 . 11, 2024 08:39 Back to list

Silent Wafer Check Valve – Efficient Flow Control Solutions

Silent Wafer Check Valve Efficient Flow Control in Diverse Applications

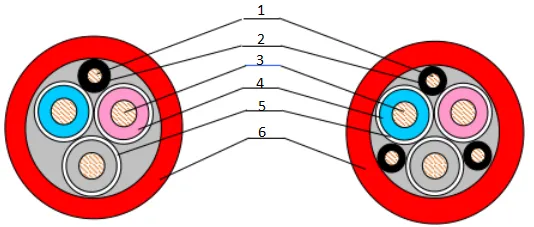

The silent wafer check valve is a pivotal component in modern fluid control systems, designed to prevent backflow while minimizing noise and pressure drops. Unlike traditional check valves, which can generate a significant amount of noise during operation, silent wafer check valves operate quietly, making them an ideal choice for a variety of applications.

Constructed for durability and efficiency, these valves typically feature a lightweight, compact profile that allows for easy installation between flanges in pipelines. Their unique design incorporates a hinge mechanism that allows the valve to open and close smoothly in response to changes in fluid direction. This ensures that the fluid flows in one direction while the valve automatically closes when backflow occurs, safeguarding the system against potential damage caused by reverse flow.

One of the main advantages of silent wafer check valves is their ability to minimize turbulence in the flow system. Traditional check valves can create a sudden drop in pressure, leading to inefficiencies and potential wear on piping systems. In contrast, silent wafer check valves provide a more streamlined flow, significantly reducing the risk of water hammer and other related issues. This not only protects the integrity of the pipes but also enhances the overall performance of the system.

silent wafer check valve

Silent wafer check valves are versatile and can be used in a variety of industries, including water treatment, HVAC, fire protection systems, and sewage management. In water treatment facilities, for instance, these valves help maintain consistent flow rates, contributing to effective filtration and treatment processes. In HVAC systems, they prevent backflow in chilled water applications, ensuring optimal performance and energy efficiency.

Furthermore, the materials used in silent wafer check valves are typically resistant to corrosion and wear, which extends their lifespan and reduces maintenance requirements. This durability, combined with their efficient design, makes them a cost-effective solution for many industrial and commercial applications.

In conclusion, silent wafer check valves represent a crucial advancement in fluid control technology. Their ability to prevent backflow while minimizing noise and pressure loss makes them an essential choice for a wide array of applications. With benefits that include durability, energy efficiency, and reduced maintenance, these valves are poised to play a significant role in enhancing the performance of fluid systems across various industries.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024