8 月 . 31, 2024 02:13 Back to list

silent wafer check valve

Silent Wafer Check Valve Ensuring Efficient Fluid Flow Management

In the world of fluid dynamics, effective management of flow is crucial in various applications, from water systems to industrial processes. One of the key components that aid in controlling this flow is the check valve. Specifically, the silent wafer check valve has gained prominence due to its unique design and operational advantages.

What is a Silent Wafer Check Valve?

A silent wafer check valve is a type of one-way valve that restricts the backflow of fluids in a system. Unlike traditional check valves, which can produce noisy slamming sounds when they close, silent wafer check valves are specifically engineered to minimize this noise. Their design incorporates a lightweight disc mechanism that allows for a smooth, gradual closure, which not only reduces noise but also enhances the valve's lifespan and overall reliability.

Design and Functionality

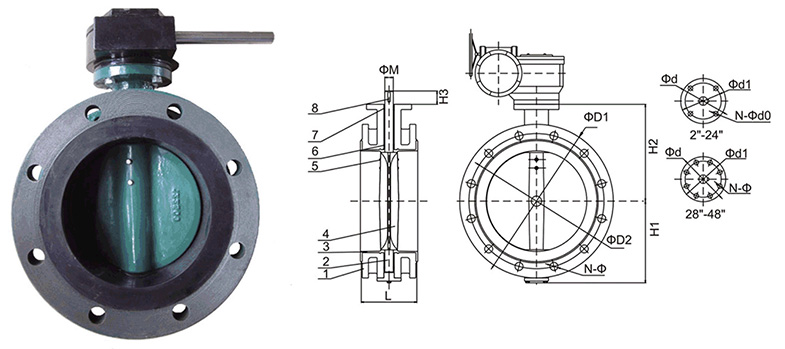

The silent wafer check valve typically features a compact, flat profile—making it ideal for installation in tight spaces. It is installed between two flanges and is often used in piping systems where a lightweight option is essential. The valve operates through the differential pressure of the fluid flowing through it. When the fluid flows in the desired direction, the disc is pushed open, allowing passage. Conversely, if the flow attempts to reverse, the disc closes seamlessly, preventing backflow.

Benefits of Using Silent Wafer Check Valves

1. Noise Reduction As the name suggests, one of the primary advantages of these valves is their silent operation. This feature is especially beneficial in residential or commercial settings where noise reduction is crucial.

2. Space Efficiency The wafer design allows these valves to be installed in limited spaces without compromising performance, making them ideal for applications in both new constructions and retrofits.

silent wafer check valve

3. Versatility Silent wafer check valves are suitable for various fluids, including water, oil, and gas, making them versatile components for a range of industries, including municipal water treatment, fire protection systems, and HVAC applications.

4. Maintenance-Free Operation With fewer moving parts compared to other types of valves, silent wafer check valves require minimal maintenance. Their simple design contributes to durability and longevity in service.

5. Cost-Effectiveness While the initial investment might be slightly higher than other check valves, the long-term savings from reduced maintenance and replacement costs make silent wafer check valves an economically sound choice.

Applications

Silent wafer check valves are widely used in various applications, including

- Water Supply Systems To prevent backflow and protect water supply from contamination. - Wastewater Management To control the flow of sewage and ensure efficient drainage. - HVAC Systems To maintain the pressure and flow of refrigerants in cooling and heating systems.

Conclusion

In summary, silent wafer check valves play a crucial role in ensuring efficient fluid flow management across multiple industries. Their noise-reducing capabilities, compact design, and low maintenance requirements make them an excellent choice for modern piping systems. As industries continue to prioritize efficiency and sustainability, the silent wafer check valve stands out as a reliable solution for fluid control challenges.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024