10 月 . 11, 2024 19:37 Back to list

Design and Applications of Semi-Lugged Butterfly Valves in Fluid Control Systems

The Semi Lugged Butterfly Valve An Overview

In the world of industrial applications, the selection of appropriate valves is crucial for the efficient operation of various systems. One notable type of valve is the semi lugged butterfly valve. This device has gained significant popularity due to its unique design and functional capabilities. In this article, we will explore the characteristics, advantages, applications, and maintenance of semi lugged butterfly valves.

Understanding the Design

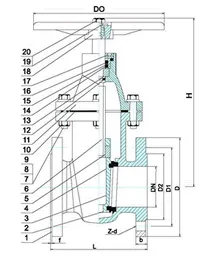

The semi lugged butterfly valve is a variant of the traditional butterfly valve and is typically comprised of a disc that rotates around a central axis within a piping system to control fluid flow. The semi lugged aspect of the design refers to the valve's mounting configuration. Unlike fully lugged valves that utilize threaded lugs for complete structural support, semi lugged valves feature lugs that provide enough support while allowing for lighter weight and easier installation. This unique configuration makes the semi lugged butterfly valve versatile and adaptable for various industries.

Advantages

1. Lightweight Construction One of the main benefits of the semi lugged design is its lightweight nature. This characteristic allows for easier handling, reduced shipping costs, and lower installation efforts compared to heavier counterparts.

2. Compact Size The compact design of semi lugged butterfly valves makes them ideal for applications where space is at a premium. Their smaller footprint means they can fit into tighter installations without compromising functionality.

3. Flow Control The rotating disc design allows for excellent flow control, enabling operators to achieve the precise flow rate required for various processes. Additionally, these valves have minimal flow resistance, resulting in energy efficiency.

4. Cost-Effectiveness Due to the simplified construction and materials used, semi lugged butterfly valves are often more cost-effective than other valve types. This affordability, combined with their durability, makes them a popular choice for many industries.

5. Versatility Semi lugged butterfly valves can be used with a wide range of fluids, including water, air, and various chemicals, making them suitable for multiple applications.

Applications

Semi lugged butterfly valves are commonly used across various sectors, including

semi lugged butterfly valve

- Water Treatment In water treatment facilities, these valves control the flow of water through filtration systems and throughout distribution networks. Their ability to handle large volumes makes them particularly valuable in these applications.

- Chemical Processing The chemical industry requires valves that can handle corrosive fluids. With appropriate material selections, semi lugged butterfly valves can operate effectively in this demanding environment.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves control airflow and help maintain desired temperatures within various regions of a building.

- Food and Beverage Industry The sanitary design options for semi lugged butterfly valves ensure compliance with health regulations, making them suitable for controlling fluid movements in food and beverage processing.

Maintenance

To ensure optimal performance and longevity, regular maintenance of semi lugged butterfly valves is essential. Key maintenance practices include

- Routine Inspections Frequent checks for signs of wear, leakage, or corrosion can help identify issues before they escalate into costly repairs.

- Lubrication Keeping the valve mechanism well-lubricated can reduce friction and wear, enhancing overall efficiency.

- Cleaning Regularly cleaning the valve, especially in applications involving viscous or particulate-laden fluids, helps prevent blockages and ensures smooth operation.

- Sealing Replacement Over time, seals can degrade, leading to leaking. Regular inspections will help determine if seal replacement is necessary.

Conclusion

The semi lugged butterfly valve is a highly functional and versatile component widely used in various industrial processes. Its lightweight design, cost-effectiveness, and excellent flow control capabilities make it an attractive option for many applications. Through proper maintenance and care, users can ensure the longevity and reliability of these valves, enabling efficient operations across different sectors. As industries continue to evolve and demand for efficient and effective solutions grow, the role of semi lugged butterfly valves will undoubtedly remain prominent in the years to come.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024