12 月 . 04, 2024 18:10 Back to list

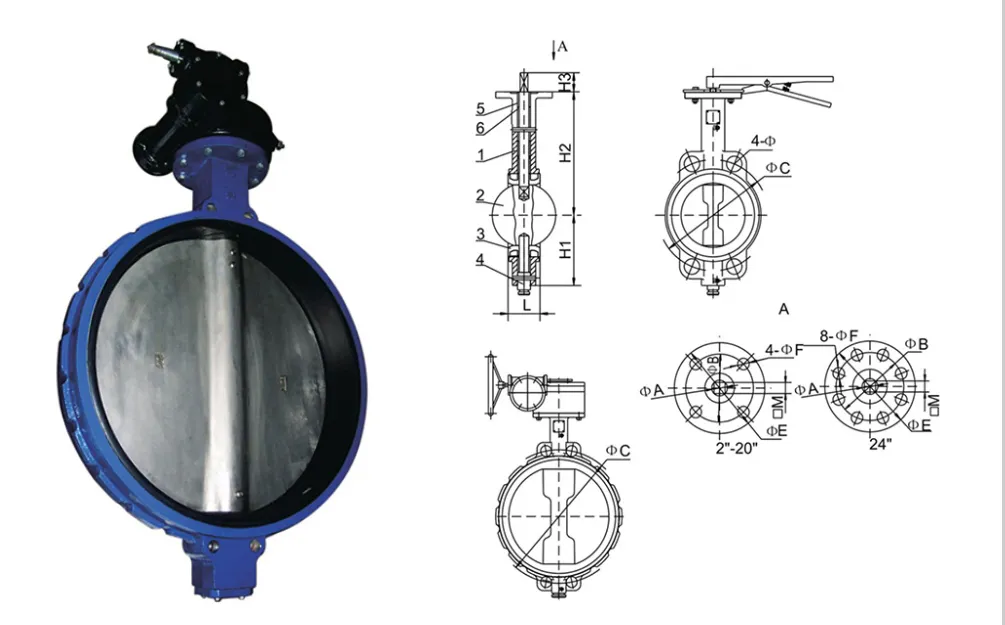

rubber lined butterfly valve

The Importance and Functionality of Rubber Lined Butterfly Valves

In the realm of industrial processes and fluid control systems, the choice of valves can significantly influence efficiency, cost, and safety. Among various types of valves, rubber lined butterfly valves have gained considerable traction due to their unique features and benefits. This article delves into the significance, functionality, and applications of rubber lined butterfly valves, providing insights into their role in modern industrial operations.

A butterfly valve is a type of quarter-turn valve that is commonly used for regulating flow. The mechanism consists of a circular disc or a blade that rotates around a diameter, effectively controlling the flow of fluid through the pipeline. The distinction of rubber lined butterfly valves lies in their lining, which is typically made from elastomeric material such as rubber, providing a protective layer over the valve body. This lining enhances the valve's resistance to corrosion, abrasion, and wear, making it suitable for a wide range of applications.

One of the primary advantages of rubber lined butterfly valves is their ability to handle corrosive fluids. In industries such as chemical processing, wastewater treatment, and mining, fluids may contain aggressive chemicals or particulates that can rapidly wear down conventional valve materials. The rubber lining acts as a barrier, protecting the valve body from damage and extending its service life. This durability translates into reduced maintenance costs and downtime, leading to improved operational efficiency and lower overall expenditure.

In addition to their protective qualities, rubber lined butterfly valves provide excellent sealing capabilities. The design of these valves allows for a tight closure, minimizing leakage during operation. This characteristic is particularly crucial in applications where fluid loss can lead to environmental hazards or safety risks. The reliable sealing properties of rubber lined butterfly valves thus play a pivotal role in ensuring compliance with safety regulations and environmental standards.

rubber lined butterfly valve

The versatility of rubber lined butterfly valves extends to their ease of installation and operation. They can be installed in various orientations, making them adaptable to different pipeline configurations. Furthermore, their lightweight design simplifies handling and installation processes, significantly reducing labor costs. With a simple quarter-turn operation, these valves allow for quick and efficient flow control, making them suitable for both manual and automated applications.

Rubber lined butterfly valves are employed across numerous sectors, highlighting their versatility. In the water and wastewater industry, they control the flow of water and waste, ensuring efficient treatment and distribution. In the food and beverage sector, these valves maintain hygiene standards while managing liquid products. The pharmaceutical industry also benefits from rubber lined butterfly valves in processes requiring high levels of cleanliness and precise fluid control.

However, like any product, rubber lined butterfly valves come with considerations regarding their limitations. The operating temperature and pressure ratings must be adhered to, as excessive conditions may compromise the integrity of the rubber lining. Additionally, while rubber provides excellent resistance to many chemicals, it may not be suitable for all applications, particularly those involving harsh solvents or extreme temperatures. Therefore, careful selection based on the specific operational environment is essential to maximize performance and longevity.

In summary, rubber lined butterfly valves represent a pivotal component in fluid control systems across diverse industries. Their corrosion resistance, excellent sealing ability, and versatility make them ideal for managing a variety of fluids, enhancing both operational efficiency and safety. As industries continue to evolve and face new challenges, the importance of effective fluid management solutions like rubber lined butterfly valves will only grow, marking them as indispensable in the pursuit of sustainability and efficiency in industrial operations. Embracing the benefits of these valves can lead to significant long-term gains for organizations in an increasingly competitive market.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024