9 月 . 30, 2024 10:26 Back to list

Understanding the Functionality and Benefits of Rubber Expansion Joints in Various Applications

Understanding Rubber Expansion Joints Essential Components in Fluid Systems

Rubber expansion joints are integral components in various industrial applications, serving to absorb vibrations, reduce noise, and accommodate thermal expansion and contraction within piping systems. Their ability to provide flexibility and mitigate stress in piping networks makes them indispensable in numerous industries, including plumbing, petrochemical, and manufacturing.

What Are Rubber Expansion Joints?

Rubber expansion joints are flexible connectors made of elastomeric materials, typically rubber, which can withstand a range of temperatures and pressures. These joints are designed to connect two sections of a pipe while allowing for movement due to thermal expansion, equipment vibrations, or misalignments. Their design features often include one or more flexible rubber bellows, which can absorb shocks and dampen vibrations.

Key Features and Benefits

1. Flexibility One of the most significant advantages of rubber expansion joints is their flexibility. This characteristic allows them to accommodate movements in all directions, including axial, lateral, and angular displacements. This flexibility is essential for maintaining the integrity of piping systems under varying temperature conditions.

2. Vibration Damping Industrial machinery often produces considerable vibrations, which can lead to equipment wear and failure over time. Rubber expansion joints act as shock absorbers, reducing the transmission of vibrations from one segment of piping to another, thereby extending the life of connected equipment.

3. Noise Reduction In addition to vibration damping, rubber expansion joints help to minimize noise generated by fluid flow and machinery. By providing a cushion between rigid components, they can significantly reduce operational noise levels, creating a more comfortable working environment.

4. Protection Against Thermal Expansion When liquids or gases are heated, they expand. This thermal expansion can create significant pressure on pipe joints, leading to damage or failure. Rubber expansion joints absorb this expansion, protecting the integrity of the piping system.

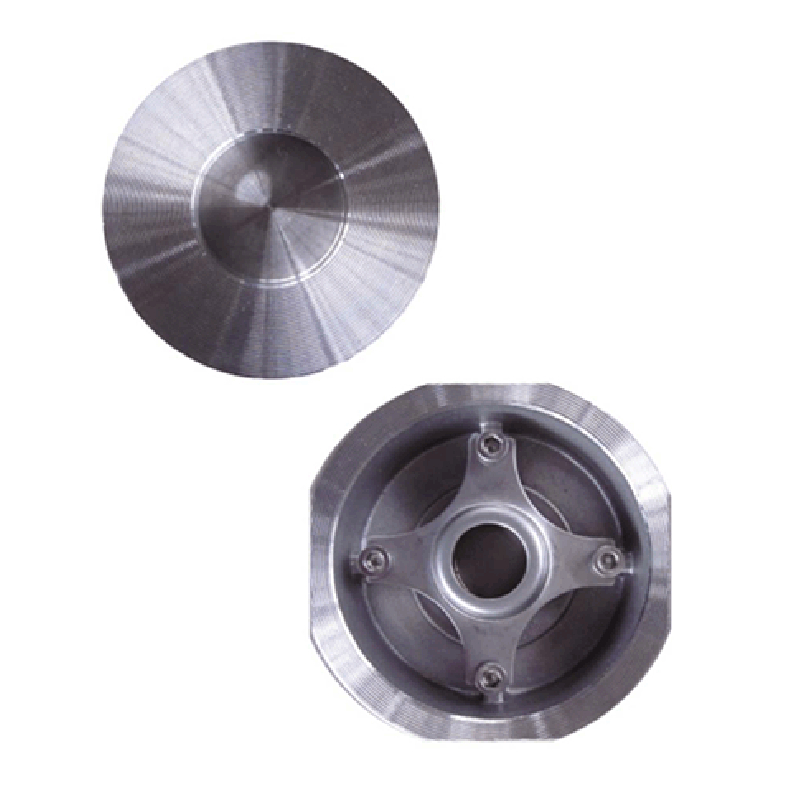

rubber expansion joint

5. Corrosion Resistance Many rubber expansion joints are designed to resist corrosion from various chemicals and fluids, enhancing their durability and lifespan. They can be engineered to withstand specific environments, including harsh chemicals and extreme temperatures.

Applications of Rubber Expansion Joints

Rubber expansion joints are utilized in a wide range of applications, including

- Industrial Piping Systems Used in water supply, wastewater treatment, and various manufacturing processes. - HVAC Systems Helps manage thermal expansion in heating, ventilation, and air conditioning systems. - Chemical Processing Used in piping systems that transport corrosive fluids, requiring materials that can resist these substances. - Power Plants Essential in turbine and generator areas where high vibrations and thermal fluctuations are prevalent.

Installation and Maintenance Considerations

While rubber expansion joints are robust and designed for longevity, proper installation and maintenance are crucial for optimal performance. Incorrect installation can lead to premature wear or failure. It is essential to ensure that the joints are aligned correctly to avoid uneven stress distribution. Regular inspections should also be conducted to check for signs of wear, cracks, or degradation, which could compromise performance.

Conclusion

Rubber expansion joints play a vital role in modern industrial piping systems, providing the flexibility, shock absorption, and protection necessary to ensure operational efficiency and equipment longevity. By understanding their features, benefits, and applications, industries can better appreciate their importance in achieving a reliable and durable fluid transport system. As technology advances, the design and materials used in rubber expansion joints continue to evolve, promising even greater performance and reliability in the future. Investing in high-quality rubber expansion joints is not just a matter of choice but a necessity for sustaining productive industrial operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024