8 月 . 31, 2024 10:58 Back to list

rubber joint plumbing fittings

Understanding Rubber Joint Plumbing Fittings A Comprehensive Guide

Rubber joint plumbing fittings are essential components utilized in various piping systems across numerous industries. Known for their flexibility, durability, and resistance to wear, these fittings play a crucial role in ensuring efficient fluid transportation. This article delves into the characteristics, advantages, applications, and maintenance of rubber joint plumbing fittings, offering insights for both homeowners and professionals in the plumbing field.

What are Rubber Joint Plumbing Fittings?

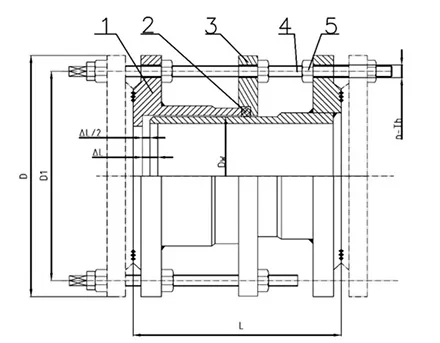

Rubber joints, also known as flexible or expansion joints, are fittings made primarily of rubber materials, often reinforced with fabric or metal to enhance strength and longevity. These fittings are designed to accommodate movement and prevent damage from vibrations, thermal expansion, and misalignment in piping systems. The rubber is usually compounded to withstand various pressures, temperatures, and chemical environments, making it suitable for a wide range of applications.

Key Characteristics

1. Flexibility The primary advantage of rubber joint plumbing fittings is their ability to flex and absorb shocks. This adaptability makes them ideal for systems that experience movement or vibration. 2. Durability Made from high-quality rubber, these fittings are highly resistant to environmental factors such as moisture, chemicals, and extreme weather conditions, ensuring longevity in various applications.

3. Easy Installation Rubber joints are generally lightweight and easy to install, allowing for quick repairs or replacements in plumbing systems.

4. Noise Reduction The rubber material effectively dampens vibrations, which helps in reducing noise levels in the piping system, a significant benefit in residential and commercial applications.

Advantages of Using Rubber Joint Plumbing Fittings

Rubber joints provide several benefits that make them a preferred choice in plumbing installations

- Cost-Effective The durability and ease of replacement of rubber joints can significantly reduce maintenance costs over time.

- Versatility They can be used in a wide range of applications, including water supply, sewage systems, HVAC installations, and industrial processes.

- Pressure Management Rubber joints can accommodate pressure fluctuations, thereby protecting the piping system from potential damage

.rubber joint plumbing fittings

- Seismic and Thermal Protection In areas prone to seismic activity or extreme temperature changes, rubber joints can minimize the risk of pipeline failure.

Applications

Rubber joint plumbing fittings are utilized in various sectors, including

- Municipal Water and Sewer Systems They are commonly found in water treatment facilities and sewage systems to handle the dynamic movements and vibrations of flowing liquids.

- HVAC Systems In heating, ventilation, and air conditioning systems, rubber joints help manage expansion and contraction due to temperature changes.

- Industrial Plumbing Many manufacturing and processing plants use rubber joints to ensure the integrity of their piping systems under extreme conditions.

Maintenance Tips

To ensure the longevity and performance of rubber joint plumbing fittings, consider the following maintenance tips

- Regular Inspections Check for signs of wear, cracks, or leaks in the rubber joints, especially in high-stress applications.

- Proper Installation Ensure that rubber joints are installed correctly to prevent issues related to misalignment or excessive pressure.

- Environmental Considerations Protect rubber fittings from exposure to harsh chemicals or extreme temperatures that could degrade the material.

In conclusion, rubber joint plumbing fittings are crucial components in maintaining the efficiency and integrity of piping systems across various industries. Their unique properties, combined with a wide range of applications, make them an indispensable choice for engineers and plumbers alike. By understanding their features, benefits, and maintenance requirements, users can maximize the performance of their plumbing systems.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024