9 月 . 19, 2024 16:35 Back to list

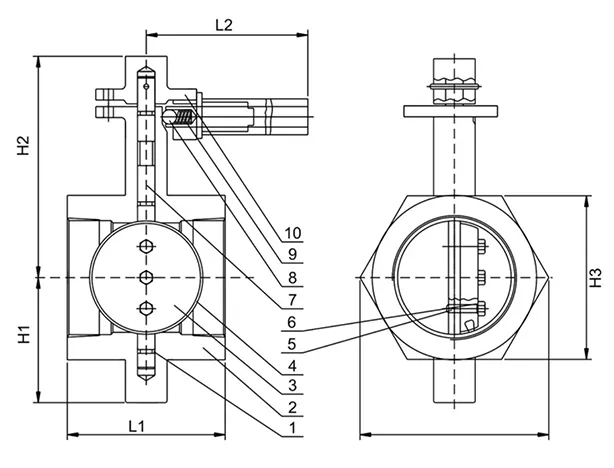

rubber check valve

Understanding Rubber Check Valves Key Features and Applications

Rubber check valves are essential components widely used in various industries for fluid and gas control applications. These valves are designed to allow fluid to flow in one direction while preventing backflow, ensuring system efficiency and safety. The uniqueness of rubber check valves lies in their construction and the materials used, often resulting in a lightweight, cost-effective, and highly efficient solution for numerous engineering challenges.

One of the primary features of rubber check valves is their elastomeric sealing element, typically made from high-quality rubber materials such as EPDM (Ethylene Propylene Diene Monomer), Nitrile, or Silicone. These materials offer excellent resistance to wear, abrasion, and various chemicals, allowing the valve to function effectively in harsh environments. The rubber diaphragm or sealing disc opens under the pressure of the incoming fluid and automatically closes when the pressure drops, thereby preventing any backflow.

Durability and reliability are key advantages of rubber check valves

. Their simple design not only minimizes the risk of leakage but also reduces maintenance costs, as there are fewer mechanical parts compared to traditional metal check valves. This characteristic makes them particularly beneficial in water and wastewater applications, where they are often used in pumping stations, irrigation systems, and drainage systems.rubber check valve

Another noteworthy aspect of rubber check valves is their versatility. They can be found in a variety of sizes and configurations, making them suitable for a wide range of applications across different industries. These include chemical processing, food and beverage, oil and gas, and HVAC systems. Furthermore, their lightweight nature facilitates easy installation in pipelines, significantly speeding up the setup process without compromising performance.

In addition to their practical applications, rubber check valves offer a level of flexibility that is unmatched by rigid valves. The rubber material can accommodate slight changes in alignment and movement within the piping system, which is particularly advantageous in environments where vibrations or settling may occur.

It's essential to select the appropriate type of rubber check valve tailored to specific application requirements. Factors such as fluid type, temperature, pressure, and the physical layout of the system all influence the choice of a suitable valve. End users must carefully consider these parameters to ensure optimal performance and longevity of the valve.

In conclusion, rubber check valves represent a crucial advancement in fluid and gas management technology. Their unique properties, including lightweight construction, excellent sealing capabilities, and resilience against various environmental factors, make them highly effective in preventing backflow and ensuring the smooth operation of different systems. As industries continue to evolve and demand more efficient solutions, rubber check valves will undoubtedly play an instrumental role in modern engineering practices, contributing to enhanced safety, reliability, and performance in fluid transport applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024