2 月 . 19, 2025 11:57 Back to list

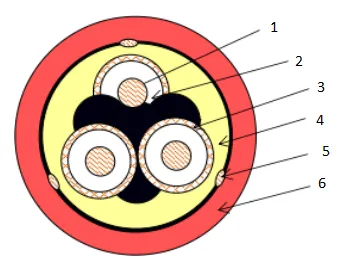

8000 Series Aluminium Alloy Conductor SER Service Entrance Cable

In the intricate world of fluid control technology, the resilient seat gate valve stands as a testament to engineering precision and durability. As an integral component in various industries, these valves are designed to regulate the flow of liquids effectively and efficiently, while maintaining a leak-proof seal when in the closed position. The advantages of resilient seat gate valves are manifold, making them an essential choice for professionals who prioritize longevity and reliability in their systems.

Furthermore, industry veterans frequently recommend resilient seat gate valves due to their minimal maintenance needs. Unlike their metal-seated counterparts, resilient seat valves do not require frequent lubrication or adjustment to maintain functionality, thus reducing downtime and operational costs. This trait particularly appeals to industries that value cost-effectiveness and reliability, such as municipal water supply systems and agricultural operations. The installation of resilient seat gate valves is also a noteworthy aspect of their expertise. Thanks to their straightforward design, they can be installed without the need for specialized tools or complex procedures. This ease of installation means reduced labor costs and shorter project timelines, which is highly beneficial for project managers overseeing large installations where time is of the essence. Finally, the robustness of resilient seat gate valves is supported by a wealth of industry-specific case studies and performance analyses. These tools provide empirical evidence of their performance capabilities over extended periods, even under harsh environmental conditions. This data serves to reassure potential buyers of their investment's soundness, reinforcing the trust professionals place in these valves. In conclusion, the resilient seat gate valve is more than just a component in fluid control systems; it is a key factor in optimizing performance and ensuring system integrity across various industries. With its comprehensive advantages in design, functionality, and reliability, coupled with a proven track record of excellence, it is clear why this valve type is a cornerstone in modern engineering solutions.

Furthermore, industry veterans frequently recommend resilient seat gate valves due to their minimal maintenance needs. Unlike their metal-seated counterparts, resilient seat valves do not require frequent lubrication or adjustment to maintain functionality, thus reducing downtime and operational costs. This trait particularly appeals to industries that value cost-effectiveness and reliability, such as municipal water supply systems and agricultural operations. The installation of resilient seat gate valves is also a noteworthy aspect of their expertise. Thanks to their straightforward design, they can be installed without the need for specialized tools or complex procedures. This ease of installation means reduced labor costs and shorter project timelines, which is highly beneficial for project managers overseeing large installations where time is of the essence. Finally, the robustness of resilient seat gate valves is supported by a wealth of industry-specific case studies and performance analyses. These tools provide empirical evidence of their performance capabilities over extended periods, even under harsh environmental conditions. This data serves to reassure potential buyers of their investment's soundness, reinforcing the trust professionals place in these valves. In conclusion, the resilient seat gate valve is more than just a component in fluid control systems; it is a key factor in optimizing performance and ensuring system integrity across various industries. With its comprehensive advantages in design, functionality, and reliability, coupled with a proven track record of excellence, it is clear why this valve type is a cornerstone in modern engineering solutions.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024