2 月 . 15, 2025 05:20 Back to list

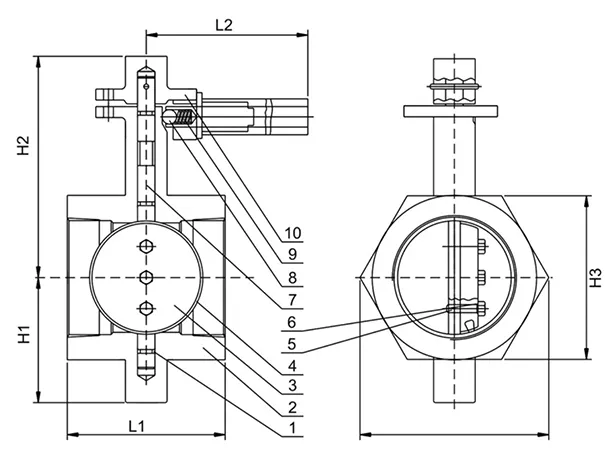

resilient seated gate valve

Resilient seated gate valves play a crucial role in various industrial and domestic water management systems. Engineered for efficiency and reliability, these valves are pivotal in ensuring seamless fluid control across diverse applications. With their unique design features, they deliver unparalleled performance, ushering in a new era of excellence in fluid management.

The operational efficiency of resilient seated gate valves is augmented by innovative design improvements such as low-torque operation, which reduces the energy and force requisite for manipulation. This feature is particularly advantageous in automated systems where valve control is integrated with digital monitoring infrastructure. Such advancements cater to modern smart-water management systems, which prioritize efficiency and resource conservation. In the realm of environmental concerns, resilient seated gate valves underscore their value by virtue of their operational safety and ecological prudence. By minimizing leakages and ensuring controlled fluid management, they mitigate inadvertent environmental impacts and reinforce sustainable practices. They offer a solution that balances high performance with an awareness of environmental stewardship, aligning with global efforts to promote sustainable industrial practices. The breadth of application for resilient seated gate valves is vast—extending from municipal water supply and treatment facilities to agricultural irrigation systems and industrial processes. Their versatility and reliability ensure that they are an essential component in any system where fluid control is paramount. In summary, resilient seated gate valves stand as a paragon of engineering excellence and operational reliability. Their innovative design features, compliance with stringent standards, and emphasis on sustainability make them indispensable in the sphere of fluid control solutions. As industries worldwide continue to evolve, the demand for high-quality, resilient seated gate valves will undoubtedly persist, reinforcing their status as a cornerstone in modern water management infrastructure.

The operational efficiency of resilient seated gate valves is augmented by innovative design improvements such as low-torque operation, which reduces the energy and force requisite for manipulation. This feature is particularly advantageous in automated systems where valve control is integrated with digital monitoring infrastructure. Such advancements cater to modern smart-water management systems, which prioritize efficiency and resource conservation. In the realm of environmental concerns, resilient seated gate valves underscore their value by virtue of their operational safety and ecological prudence. By minimizing leakages and ensuring controlled fluid management, they mitigate inadvertent environmental impacts and reinforce sustainable practices. They offer a solution that balances high performance with an awareness of environmental stewardship, aligning with global efforts to promote sustainable industrial practices. The breadth of application for resilient seated gate valves is vast—extending from municipal water supply and treatment facilities to agricultural irrigation systems and industrial processes. Their versatility and reliability ensure that they are an essential component in any system where fluid control is paramount. In summary, resilient seated gate valves stand as a paragon of engineering excellence and operational reliability. Their innovative design features, compliance with stringent standards, and emphasis on sustainability make them indispensable in the sphere of fluid control solutions. As industries worldwide continue to evolve, the demand for high-quality, resilient seated gate valves will undoubtedly persist, reinforcing their status as a cornerstone in modern water management infrastructure.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024