2 月 . 16, 2025 04:58 Back to list

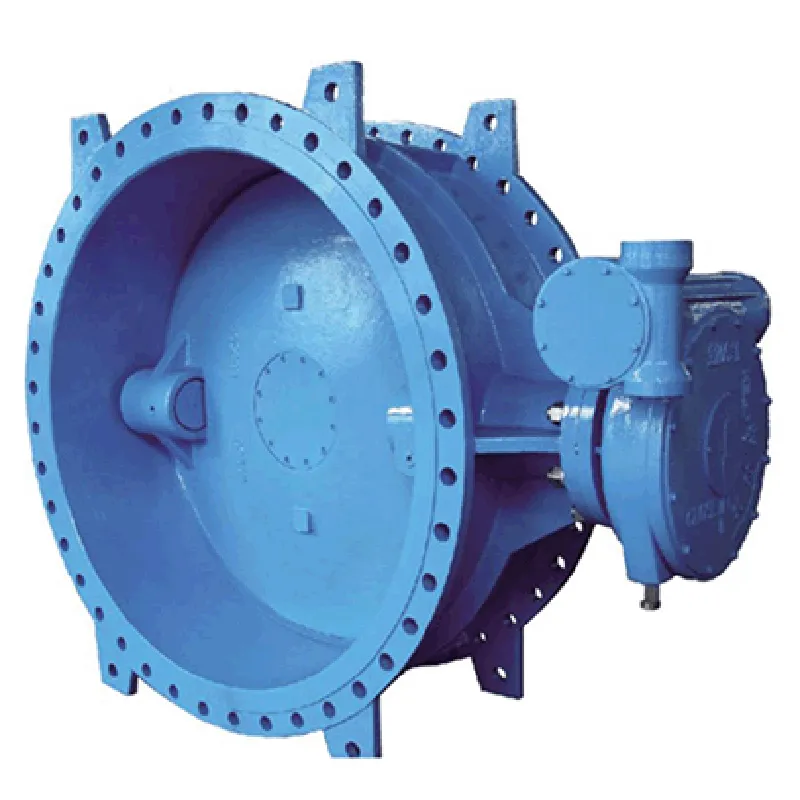

reflex rubber expansion joint

The role of reflex rubber expansion joints in industrial applications cannot be overstated. As the industrial landscape continues to evolve, so does the demand for components that can withstand dynamic environmental stresses without compromising on durability or performance. Reflex rubber expansion joints, often overlooked, serve as critical solutions in various sectors due to their flexibility, resilience, and adaptability.

Furthermore, the authority and trustworthiness of companies producing reflex rubber expansion joints are critical. Established brands not only adhere to international standards like ASTM or ISO but also invest in continuous research and development to innovate and improve their products. For instance, incorporating advancements such as enhanced fabric reinforcements or specialized rubber compounds can significantly boost the joint's capabilities, providing solutions that are both cutting-edge and reliable. In terms of real-world experience, operators and engineers consistently report improved system efficiency and reduced maintenance costs with the implementation of high-quality reflex rubber expansion joints. Field studies demonstrate that these components can extend the service life of pipelines and other related systems by effectively managing the mechanical stress and vibrations commonly experienced in industrial operations. This directly translates to minimized downtime and operational expenditure, bolstering the case for their integration in both new and existing setups. Ultimately, reflex rubber expansion joints are indispensable in creating and maintaining robust industrial systems. Their contribution to enhancing system resilience, coupled with the manufacturer's expertise and commitment to quality, underscores their critical role in modern engineering solutions. As industries continue to push the boundaries of what is possible, investing in the right expansion joints is a strategic decision that promises long-term benefits and enduring peace of mind.

Furthermore, the authority and trustworthiness of companies producing reflex rubber expansion joints are critical. Established brands not only adhere to international standards like ASTM or ISO but also invest in continuous research and development to innovate and improve their products. For instance, incorporating advancements such as enhanced fabric reinforcements or specialized rubber compounds can significantly boost the joint's capabilities, providing solutions that are both cutting-edge and reliable. In terms of real-world experience, operators and engineers consistently report improved system efficiency and reduced maintenance costs with the implementation of high-quality reflex rubber expansion joints. Field studies demonstrate that these components can extend the service life of pipelines and other related systems by effectively managing the mechanical stress and vibrations commonly experienced in industrial operations. This directly translates to minimized downtime and operational expenditure, bolstering the case for their integration in both new and existing setups. Ultimately, reflex rubber expansion joints are indispensable in creating and maintaining robust industrial systems. Their contribution to enhancing system resilience, coupled with the manufacturer's expertise and commitment to quality, underscores their critical role in modern engineering solutions. As industries continue to push the boundaries of what is possible, investing in the right expansion joints is a strategic decision that promises long-term benefits and enduring peace of mind.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024