9 月 . 24, 2024 19:07 Back to list

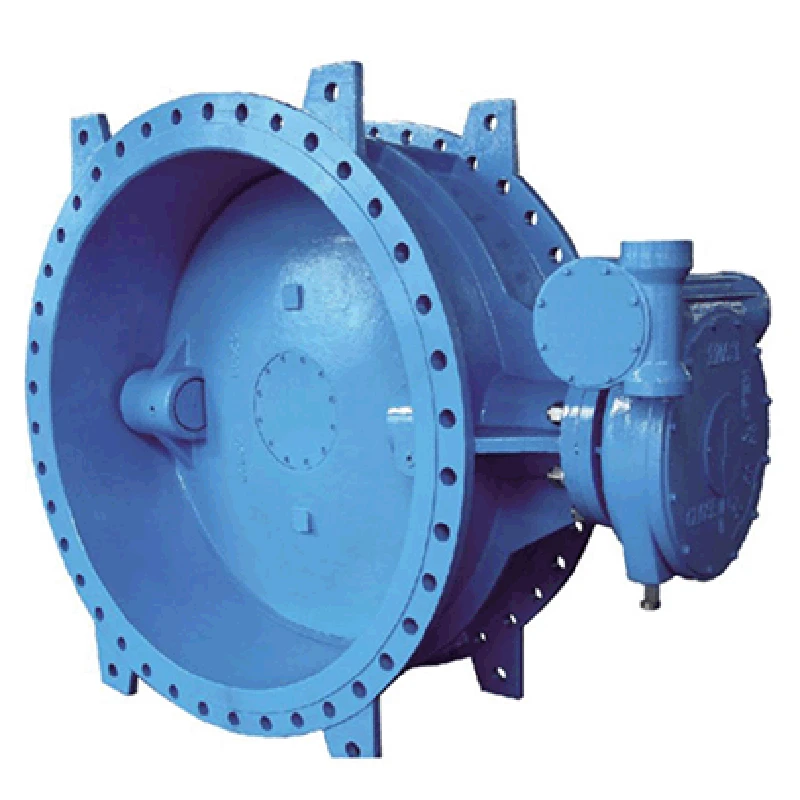

pressure valve air compressor

The Importance of Pressure Valve in Air Compressors

Air compressors are essential tools in various industries, from manufacturing and construction to automotive and HVAC systems. Their ability to convert power into potential energy stored in compressed air enhances productivity and efficiency on job sites. One crucial component within air compressors is the pressure valve, which plays a vital role in maintaining safe and efficient operation.

Understanding the Pressure Valve

A pressure valve, often referred to as a pressure relief valve or pressure regulating valve, is designed to control the pressure within the compressor system. It ensures that the pressure remains within a safe range, preventing over-pressurization, which can lead to mechanical failure or, in extreme cases, explode. The pressure valve acts as a safeguard, releasing excess pressure when it exceeds a predetermined limit.

Functionality and Mechanism

The pressure valve operates by monitoring the pressure levels within the air tank or compressor system. When the pressure reaches a set threshold, the valve opens and allows excess air to escape, effectively lowering the pressure. This mechanism not only protects the compressor but also enhances the longevity of the equipment by preventing undue stress on its components.

In many air compressors, pressure valves are adjustable, allowing users to set specific pressure limits according to their operational requirements. This flexibility is crucial for applications that demand varying pressure levels, such as spray painting, pneumatic tools, and inflating tires.

Safety and Efficiency

pressure valve air compressor

The presence of a pressure valve is paramount for the safety of both the equipment and the personnel operating it. Over-pressurization can cause catastrophic failures, leading to costly downtime and potential injuries. By incorporating a reliable pressure valve, companies can mitigate these risks and create a safer working environment.

Moreover, a well-functioning pressure valve contributes to operational efficiency. By maintaining optimal pressure levels, the air compressor can run more effectively, leading to lower energy consumption. This efficiency translates into reduced operational costs, making it a smart investment for businesses reliant on compressed air systems.

Maintenance and Inspection

Regular maintenance and inspection of the pressure valve are critical to ensuring its proper functioning. Users should routinely check for any signs of wear, corrosion, or malfunction. If a pressure valve does not operate correctly, it can lead to issues such as inaccurate pressure readings, inefficient air supply, and increased wear on the compressor system.

Maintenance tasks may include cleaning the valve, checking the spring load, and ensuring that there are no blockages in the valve body. It is also advisable to consult the manufacturer's guidelines for specific maintenance schedules and procedures tailored to the model in use.

Conclusion

In conclusion, the pressure valve is a vital component of air compressors that ensures safe and efficient operation. Its ability to regulate and relieve pressure plays a crucial role in protecting equipment and maintaining optimal performance. By understanding the importance of the pressure valve and implementing regular maintenance practices, businesses can enhance the longevity and reliability of their air compressor systems. Whether in construction, manufacturing, or any other field that relies on compressed air, recognizing the value of a pressure valve can lead to safer and more efficient operations.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024