10 月 . 21, 2024 09:00 Back to list

Pneumatic Control Solutions for Efficient Butterfly Valve Operation and Performance

Understanding Pneumatic Butterfly Valves Function, Applications, and Advantages

In the realm of fluid control systems, pneumatic butterfly valves play a pivotal role in regulating the flow of liquids and gases. These valves leverage pneumatic actuators to swiftly open or close the valve disc, enabling precise control over the flow rate. The design and functionality of pneumatic butterfly valves make them ideal for a variety of industrial applications, from water treatment and chemical processing to HVAC systems and food manufacturing.

The Mechanism of Pneumatic Butterfly Valves

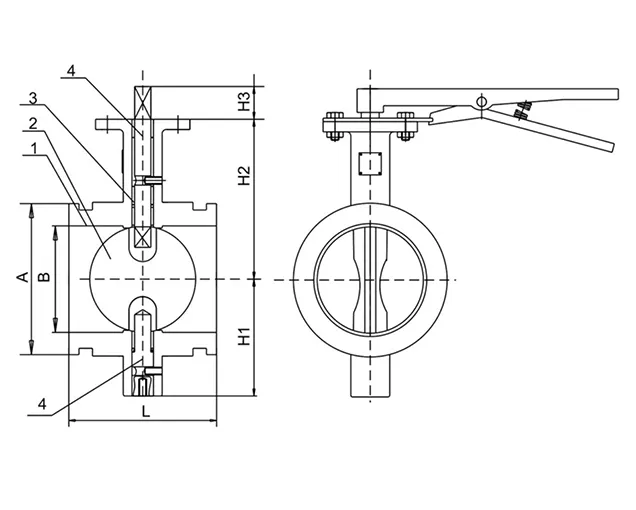

A pneumatic butterfly valve consists of a circular disc or plate that pivots around a shaft. The valve's design is relatively simple, yet effective. When the actuator imparts a pneumatic force, it causes the disc to rotate, either allowing for unrestricted flow when fully open or blocking flow entirely when in the closed position. The linear motion provided by the pneumatic actuator translates efficiently into angular motion, which allows for rapid operation and minimal pressure drop across the valve.

These valves are usually made from durable materials such as stainless steel, PVC, or various alloys, ensuring longevity and corrosion resistance in harsh environments. A key feature of pneumatic butterfly valves is their compact size, which allows for easy installation in tight spaces while maintaining high flow efficiency.

Applications of Pneumatic Butterfly Valves

Pneumatic butterfly valves find their applications in various industries due to their unique advantages.

1. Water Treatment Plants These valves are commonly used for controlling the flow of water, chemicals, and slurries, thanks to their ability to handle large volumes with relative ease.

2. Chemical Processing In the chemical industry, precise control of fluid flow is critical. Pneumatic butterfly valves facilitate this control while also being resistant to corrosive substances.

4. Food and Beverage Due to their easy-to-clean designs, pneumatic butterfly valves are ideal for food processing, where maintaining hygiene standards is paramount.

pneumatic butterfly valve

5. Oil and Gas In this sector, these valves are used in various applications, including pipeline flow control and processing systems, where durable materials are essential.

Advantages of Pneumatic Butterfly Valves

The popularity of pneumatic butterfly valves can be attributed to several advantages they offer

1. Fast Operation The pneumatic actuator allows for quick opening and closing. This rapid response time is crucial in processes where timely adjustments are necessary.

2. Minimal Space Requirements Compared to traditional valve types, such as globe or gate valves, butterfly valves are more compact, making them suitable for applications where space is limited.

3. Low Maintenance With fewer moving parts, pneumatic butterfly valves demand less maintenance than other valve types, leading to lower operational costs.

4. Versatility These valves can be used in a wide range of pressures and temperatures, allowing for versatility across various industrial processes.

5. Efficient Flow Control The design minimizes turbulence in the fluid flow, which enhances overall system efficiency and reduces energy consumption.

Conclusion

Pneumatic butterfly valves are an indispensable component in modern fluid control systems, offering reliable performance across numerous industries. Their efficient design, coupled with the rapid actuation capabilities provided by pneumatic power, makes them ideal for a variety of applications, from water treatment to chemical processing and beyond. As industries continue to evolve, the demand for effective fluid control solutions will only increase, solidifying the place of pneumatic butterfly valves in the future of automation and process management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024