1 月 . 22, 2025 04:27 Back to list

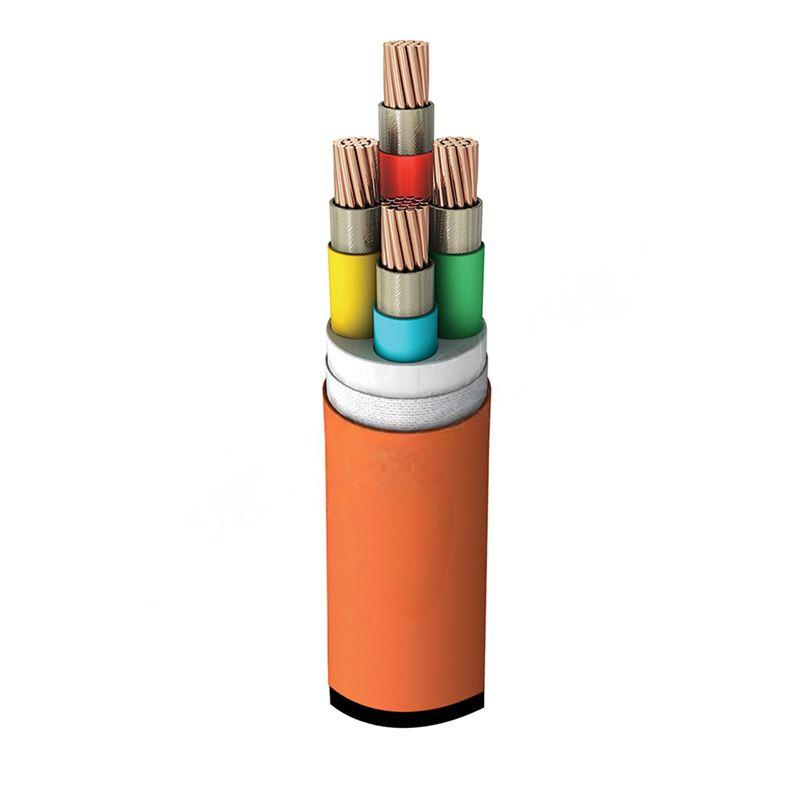

Type W Two-Conductor Portable Power Cable 2kV

The PN16 check valve is a critical component for ensuring the reliability and safety of various piping systems. Its primary function is to prevent the backflow of media, such as water or gas, thus protecting the integrity of the system and preventing potential damage. Understanding the nuances of this valve, its installation, operation, and maintenance is crucial for optimizing its performance.

Trustworthiness is an essential consideration in the selection of a PN16 check valve. Investing in products from reputable manufacturers who offer comprehensive warranties and support services ensures that you are not only getting a top-quality product but also the assurance of technical support when necessary. Transparent supply chains and rigorous testing protocols indicate a manufacturer’s commitment to product integrity, further enhancing trust in their products. Installation and maintenance of a PN16 check valve significantly impact its effectiveness and lifespan. Proper installation involves ensuring that the flow direction is correctly aligned, as indicated on the valve, and that all connection points are sealed to prevent leaks. It's advisable for maintenance personnel to routinely inspect valves for wear and tear, as well as verify that no debris is obstructing the flow path. Routine checks and timely interventions can avert potential malfunctions, which underscores the necessity of a well-documented maintenance schedule. Moreover, advanced materials and modern engineering have introduced enhancements to the traditional PN16 check valve designs. For instance, valves made from stainless steel or brass provide increased resistance to corrosion, which is particularly advantageous in challenging environments. Utilization of composite materials or the addition of elastomer seals further augments the valve’s strength and sealing capability, providing an additional layer of protection against leaks and ensuring maximum efficiency. In conclusion, the PN16 check valve is an indispensable asset in many industrial and domestic applications. Its design and specification cater to a range of pressure environments, offering a blend of performance and durability. Through diligent selection based on expert advice, authoritative knowledge, and a focus on trustworthy sourcing, systems remain protected from the hazards of backflow. Proper installation and rigorous maintenance amplify these benefits, resulting in a sustainable and safe operational pipeline. For industries seeking reliable solutions that balance innovation with classic engineering principles, the PN16 check valve represents a tried, tested, and true component pivotal to system integrity and safety.

Trustworthiness is an essential consideration in the selection of a PN16 check valve. Investing in products from reputable manufacturers who offer comprehensive warranties and support services ensures that you are not only getting a top-quality product but also the assurance of technical support when necessary. Transparent supply chains and rigorous testing protocols indicate a manufacturer’s commitment to product integrity, further enhancing trust in their products. Installation and maintenance of a PN16 check valve significantly impact its effectiveness and lifespan. Proper installation involves ensuring that the flow direction is correctly aligned, as indicated on the valve, and that all connection points are sealed to prevent leaks. It's advisable for maintenance personnel to routinely inspect valves for wear and tear, as well as verify that no debris is obstructing the flow path. Routine checks and timely interventions can avert potential malfunctions, which underscores the necessity of a well-documented maintenance schedule. Moreover, advanced materials and modern engineering have introduced enhancements to the traditional PN16 check valve designs. For instance, valves made from stainless steel or brass provide increased resistance to corrosion, which is particularly advantageous in challenging environments. Utilization of composite materials or the addition of elastomer seals further augments the valve’s strength and sealing capability, providing an additional layer of protection against leaks and ensuring maximum efficiency. In conclusion, the PN16 check valve is an indispensable asset in many industrial and domestic applications. Its design and specification cater to a range of pressure environments, offering a blend of performance and durability. Through diligent selection based on expert advice, authoritative knowledge, and a focus on trustworthy sourcing, systems remain protected from the hazards of backflow. Proper installation and rigorous maintenance amplify these benefits, resulting in a sustainable and safe operational pipeline. For industries seeking reliable solutions that balance innovation with classic engineering principles, the PN16 check valve represents a tried, tested, and true component pivotal to system integrity and safety.

Share

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024