2 月 . 16, 2025 07:35 Back to list

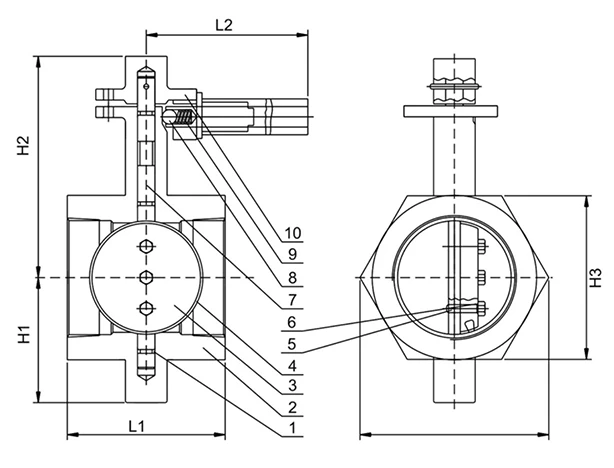

pipe dismantling joint

Pipe dismantling joints play a crucial role in various industries where pipeline systems are extensively used. These products are vital for maintaining the functionality and efficiency of fluid transport systems across a myriad of sectors, including water treatment, oil and gas, and chemical processing.

Trustworthiness is paramount when selecting a provider for pipe dismantling joints. Reliable suppliers will have a proven track record, evidenced by testimonials and case studies from satisfied clients. They will offer robust warranties and support services, ensuring that any potential issues are promptly addressed. Trustworthy companies often host extensive training programs for their products, educating customers on proper installation and maintenance procedures to extend the lifespan of these critical components. For pipeline operators, incorporating pipe dismantling joints translates to enhanced operational efficiency and cost-effectiveness. These products are not mere accessories; they are strategic investments that bolster the resilience and adaptability of pipeline systems. By allowing swift and safe access to pipelines, they minimize operational interruptions, which is crucial in industries where downtime equates to substantial financial loss. In summary, pipe dismantling joints are indispensable assets in the management of complex pipeline systems. Their role in ensuring seamless operations through maintenance ease, paired with the backing of authoritative and trustworthy manufacturers, makes them vital tools in industry. The adoption of these joints reflects a broader commitment to maximizing efficiency, reliability, and safety in pipeline infrastructure. As industries continue to advance and evolve, the integration of such essential components becomes increasingly critical, underscoring their enduring value.

Trustworthiness is paramount when selecting a provider for pipe dismantling joints. Reliable suppliers will have a proven track record, evidenced by testimonials and case studies from satisfied clients. They will offer robust warranties and support services, ensuring that any potential issues are promptly addressed. Trustworthy companies often host extensive training programs for their products, educating customers on proper installation and maintenance procedures to extend the lifespan of these critical components. For pipeline operators, incorporating pipe dismantling joints translates to enhanced operational efficiency and cost-effectiveness. These products are not mere accessories; they are strategic investments that bolster the resilience and adaptability of pipeline systems. By allowing swift and safe access to pipelines, they minimize operational interruptions, which is crucial in industries where downtime equates to substantial financial loss. In summary, pipe dismantling joints are indispensable assets in the management of complex pipeline systems. Their role in ensuring seamless operations through maintenance ease, paired with the backing of authoritative and trustworthy manufacturers, makes them vital tools in industry. The adoption of these joints reflects a broader commitment to maximizing efficiency, reliability, and safety in pipeline infrastructure. As industries continue to advance and evolve, the integration of such essential components becomes increasingly critical, underscoring their enduring value.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024