2 月 . 10, 2025 11:31 Back to list

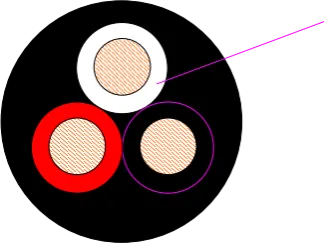

pipe dismantling joint

Pipe dismantling joints are an essential component in modern piping systems, providing the flexibility and reliability needed in a wide range of industries, from water treatment facilities to industrial plants. Designed to facilitate the installation, maintenance, and replacement of pipes, these joints bring numerous advantages that support efficient operations within complex piping networks.

Trustworthiness is a crucial factor when selecting pipe dismantling joints, and the top manufacturers in this niche have built their reputations on providing dependable products. Genuine user testimonials often underscore the robustness and ease of installation these joints offer. Furthermore, warranty policies extended by reputable manufacturers provide an additional layer of security, assuring buyers of the products’ quality and performance. Trust is also fostered through customer support services, which are crucial for addressing any concerns during the joint's lifespan and ensuring that clients get the most out of their investment. From a product perspective, pipe dismantling joints are versatile, catering to a variety of applications. Whether used in urban water supply systems or isolated industrial scenarios, they play a pivotal role in simplifying pipe management. Their design typically features adjustable bolts and nuts, allowing for movement in multiple directions, which significantly aids in aligning and connecting misaligned pipes. This adaptability is particularly advantageous in confined spaces or areas where precision alignment is challenging. Moreover, innovations in the design and functionality of pipe dismantling joints continue to emerge, such as the incorporation of advanced sealing technologies that further minimize leak risks and maintain system pressure efficiently. Industry leaders in dismantling joint manufacturing are continually pushing the envelope, integrating smart sensing technologies to improve monitoring capabilities and predictive maintenance outcomes. In conclusion, pipe dismantling joints are a crucial component in any piping network, combining experience-backed usability, expert engineering, and authoritative safety standards to offer a trustworthy solution. For businesses relying on robust piping infrastructure, investing in high-quality dismantling joints ensures operational continuity, cost savings, and system longevity. As technology advances, so too will the capabilities of these essential joints, promising even greater reliability and ease of use in future applications.

Trustworthiness is a crucial factor when selecting pipe dismantling joints, and the top manufacturers in this niche have built their reputations on providing dependable products. Genuine user testimonials often underscore the robustness and ease of installation these joints offer. Furthermore, warranty policies extended by reputable manufacturers provide an additional layer of security, assuring buyers of the products’ quality and performance. Trust is also fostered through customer support services, which are crucial for addressing any concerns during the joint's lifespan and ensuring that clients get the most out of their investment. From a product perspective, pipe dismantling joints are versatile, catering to a variety of applications. Whether used in urban water supply systems or isolated industrial scenarios, they play a pivotal role in simplifying pipe management. Their design typically features adjustable bolts and nuts, allowing for movement in multiple directions, which significantly aids in aligning and connecting misaligned pipes. This adaptability is particularly advantageous in confined spaces or areas where precision alignment is challenging. Moreover, innovations in the design and functionality of pipe dismantling joints continue to emerge, such as the incorporation of advanced sealing technologies that further minimize leak risks and maintain system pressure efficiently. Industry leaders in dismantling joint manufacturing are continually pushing the envelope, integrating smart sensing technologies to improve monitoring capabilities and predictive maintenance outcomes. In conclusion, pipe dismantling joints are a crucial component in any piping network, combining experience-backed usability, expert engineering, and authoritative safety standards to offer a trustworthy solution. For businesses relying on robust piping infrastructure, investing in high-quality dismantling joints ensures operational continuity, cost savings, and system longevity. As technology advances, so too will the capabilities of these essential joints, promising even greater reliability and ease of use in future applications.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024