11 月 . 04, 2024 13:02 Back to list

pipe dismantling joint

Understanding Pipe Dismantling Joints A Key Component in Pipeline Systems

In the world of industrial piping systems, managing and maintaining pipelines efficiently is critical for operational success. One essential component that plays a crucial role in this regard is the pipe dismantling joint. This article will explore the purpose, design, and benefits of these joints, emphasizing why they are indispensable in pipeline installations.

What is a Pipe Dismantling Joint?

A pipe dismantling joint, often referred to as a dismantling joint or a pipe end joint, is an engineered fitting used to facilitate the disassembly and reconfiguration of pipe sections. It serves as a flexible connection between two pipe segments, allowing for easy access for maintenance, repair, or system upgrades without the need for dismantling the entire pipeline.

Typically, dismantling joints are found in various types of pipelines, including water supply systems, heating and cooling systems, and industrial process pipelines. They enable users to isolate sections of the piping system, making it easier to replace or repair valves, pumps, or other critical components without disrupting the entire network.

Design Features

Dismantling joints are designed with several innovative features that enhance their functionality. The most notable elements include

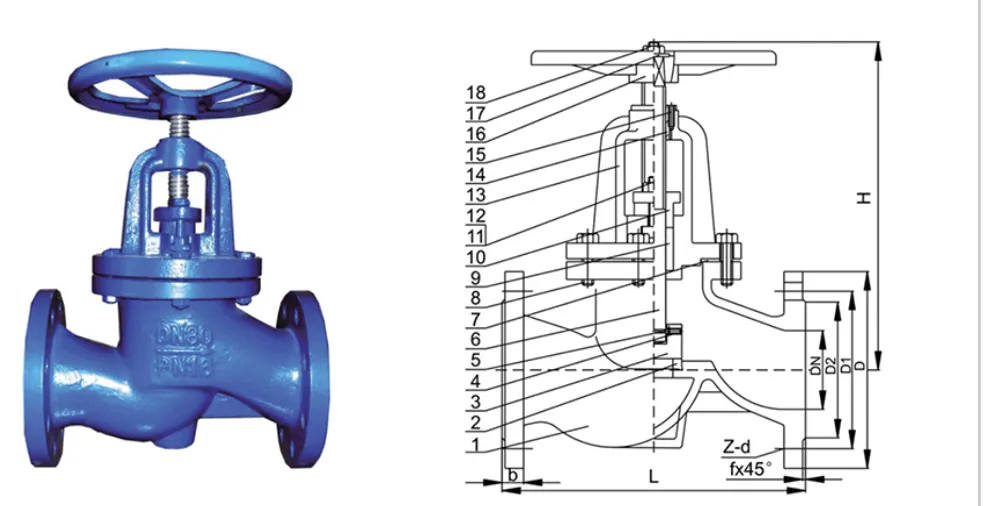

1. Adjustable Length Many dismantling joints offer adjustable lengths, allowing for precise alignment and fitting with existing pipes. This flexibility is particularly valuable in older systems where alignment may have shifted over time.

2. Robust Materials These joints are typically constructed from durable materials such as ductile iron, stainless steel, or carbon steel to withstand high pressures and corrosive environments, ensuring long-lasting performance.

3. Sealing Mechanisms Effective sealing is crucial in preventing leaks and ensuring operational efficiency. Most dismantling joints incorporate advanced sealing technology, such as rubber gaskets or O-rings, to maintain a secure connection.

pipe dismantling joint

4. Easy Installation and Operation The design of dismantling joints allows for quick installation and removal, minimizing downtime during maintenance activities. This efficiency is essential for maintaining continuous operations in industries where time is money.

Benefits of Using Dismantling Joints

The inclusion of dismantling joints in a piping system offers numerous advantages

1. Maintenance Efficiency By providing easy access to critical components, dismantling joints significantly reduce the time and labor required for maintenance tasks. This leads to lower operating costs and better resource management.

2. System Flexibility Dismantling joints enhance the flexibility of a piping system, allowing for modifications and expansions with minimal disruption. This adaptability is vital in industries where processes frequently change or evolve.

3. Enhanced Safety The ability to isolate sections of a pipeline without compromising the entire system enhances safety for employees and the environment. This is particularly important in systems that transport hazardous materials.

4. Cost Savings Ultimately, the efficiency, safety, and flexibility provided by dismantling joints can lead to significant cost savings over the lifecycle of a piping system, making them a worthwhile investment.

Conclusion

In conclusion, pipe dismantling joints serve an essential purpose in modern piping systems. Their innovative design and myriad benefits make them invaluable for maintenance, flexibility, and overall system integrity. By investing in quality dismantling joints, industries can ensure smoother operations, enhance safety, and ultimately save costs—a win-win for any organization managing extensive piping infrastructure.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024