2 月 . 10, 2025 11:46 Back to list

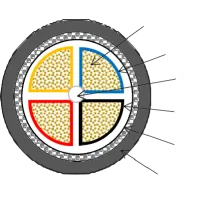

non rising stem gate valve

In the world of industrial plumbing and water management, the non-rising stem gate valve stands as a vital innovation, offering unmatched benefits in scenarios where space and reliability are primary concerns. These unique valves, distinct in design and function, play a critical role in numerous applications ranging from municipal water systems to large-scale industrial installations. Their popularity hinges not only on their compact form but also their operational efficiency and longevity.

Authoritativeness in this area is underscored by the adherence of non-rising stem gate valves to strict industry standards and regulations. Compliance with these standards—such as those set by the American Water Works Association (AWWA) and other international regulatory bodies—ensures that these valves not only meet but exceed the required safety and performance benchmarks. Manufacturers often subject these valves to rigorous testing under simulated field conditions to validate their reliability, demonstrating their commitment to delivering only the best products to the market. Trustworthiness of non-rising stem gate valves is further established by the wealth of positive testimonials and case studies from those who have deployed them in various sectors. Users frequently report significant improvements in system efficiency and reductions in maintenance costs and downtime. The straightforward design reduces the potential for mechanical failure, which is often a concern in systems where reliability is non-negotiable. Furthermore, the ease of operation, even after prolonged periods of non-use, solidifies their status as dependable components in any piping infrastructure. In addition to these performance and operational benefits, the adaptability of non-rising stem gate valves makes them suitable for retrofitting into existing systems. Their installation does not require extensive modifications, providing a seamless integration that minimizes operational disruptions. This aspect is particularly beneficial when modernizing facilities, allowing industries to upgrade their systems with minimal investment while reaping substantial long-term benefits. Ultimately, non-rising stem gate valves embody a blend of thoughtful engineering, robust construction, and regulatory compliance, positioning them as a preferred choice for industry professionals worldwide. Their contribution to the efficiency, safety, and reliability of vital systems cannot be overstated, making them an indispensable component in the toolkit of engineers and facility managers aiming for excellence in fluid control management. As the demands on infrastructure continue to grow, the role of these valves will undoubtedly expand, further cementing their importance in industrial ingenuity and operational sustainability.

Authoritativeness in this area is underscored by the adherence of non-rising stem gate valves to strict industry standards and regulations. Compliance with these standards—such as those set by the American Water Works Association (AWWA) and other international regulatory bodies—ensures that these valves not only meet but exceed the required safety and performance benchmarks. Manufacturers often subject these valves to rigorous testing under simulated field conditions to validate their reliability, demonstrating their commitment to delivering only the best products to the market. Trustworthiness of non-rising stem gate valves is further established by the wealth of positive testimonials and case studies from those who have deployed them in various sectors. Users frequently report significant improvements in system efficiency and reductions in maintenance costs and downtime. The straightforward design reduces the potential for mechanical failure, which is often a concern in systems where reliability is non-negotiable. Furthermore, the ease of operation, even after prolonged periods of non-use, solidifies their status as dependable components in any piping infrastructure. In addition to these performance and operational benefits, the adaptability of non-rising stem gate valves makes them suitable for retrofitting into existing systems. Their installation does not require extensive modifications, providing a seamless integration that minimizes operational disruptions. This aspect is particularly beneficial when modernizing facilities, allowing industries to upgrade their systems with minimal investment while reaping substantial long-term benefits. Ultimately, non-rising stem gate valves embody a blend of thoughtful engineering, robust construction, and regulatory compliance, positioning them as a preferred choice for industry professionals worldwide. Their contribution to the efficiency, safety, and reliability of vital systems cannot be overstated, making them an indispensable component in the toolkit of engineers and facility managers aiming for excellence in fluid control management. As the demands on infrastructure continue to grow, the role of these valves will undoubtedly expand, further cementing their importance in industrial ingenuity and operational sustainability.

Share

Prev:

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024