10 月 . 13, 2024 06:32 Back to list

non return ball valve

Understanding Non-Return Ball Valves Functionality and Applications

Non-return ball valves, also known as check valves, are essential components in many industrial and mechanical applications. These devices are designed to ensure the unidirectional flow of fluids, preventing backflow and safeguarding the integrity of various systems. In this article, we will explore the functionality, design, and applications of non-return ball valves, highlighting their significance in modern engineering.

Functionality of Non-Return Ball Valves

The primary purpose of a non-return ball valve is to allow fluid to flow in one direction while blocking reverse flow. This is achieved through a simple yet effective mechanism a ball that is positioned inside the valve body. When the fluid flows in the designated direction, the ball is pushed away from its seat, allowing passage. Conversely, if there is an attempt at backflow, the ball is pushed against the seat, creating a tight seal that prevents any reverse flow.

This mechanism relies on the pressure differential between the two sides of the valve. The higher pressure of the incoming fluid effectively lifts the ball off its seat, while a decrease in pressure or reverse flow results in the ball falling back into place. As a result, non-return ball valves are particularly effective in applications involving pumping systems, where the prevention of backflow is crucial for maintaining system integrity and efficiency.

Design and Construction

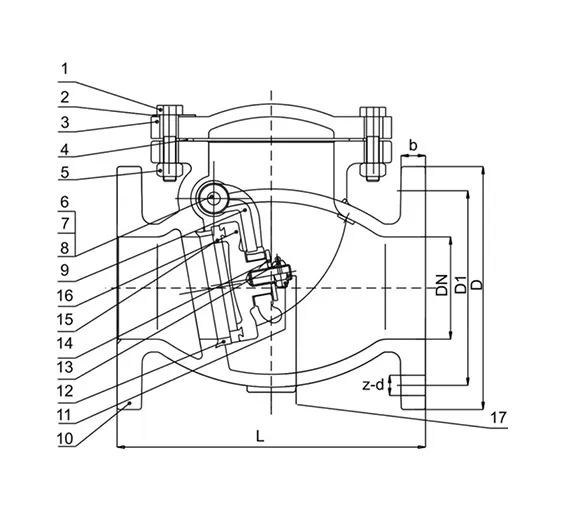

Non-return ball valves typically consist of several key components the valve body, the ball, the seat, and often, a spring mechanism. The valve body is usually made from durable materials such as stainless steel, brass, or plastic, depending on the application. The ball is often constructed from materials that can withstand the specific conditions of the fluid being transported, including temperature and chemical compatibility.

The seat, where the ball makes contact to create a seal, is also crucial in determining the valve’s effectiveness. It must provide a reliable sealing surface without deforming over time. In some designs, a spring mechanism is included, which helps return the ball to its seated position more effectively in low-pressure situations.

Advantages of Using Non-Return Ball Valves

Non-return ball valves offer several advantages that make them a popular choice for many applications

non return ball valve

1. Reliable Backflow Prevention The primary function of these valves is to prevent backflow, which can cause system damage or contamination. Their ability to effectively seal against reverse flow contributes to system safety.

2. Low Maintenance Non-return ball valves generally require minimal maintenance. Their simple design means fewer moving parts, reducing the likelihood of failure due to wear and tear.

3. Versatile Applications These valves are suitable for various fluids, including water, oil, and gases. This versatility makes them useful in numerous industries, from oil and gas to water treatment and chemical processing.

4. Quick Response The mechanism of the ball valve allows for a quick response to changes in flow direction, enhancing the reliability of fluid systems.

Applications

Non-return ball valves find use in a variety of applications, including

- Pumping Systems Used in water and wastewater treatment plants to prevent backflow and protect pumps. - Fluid Transport Employed in pipelines where directional flow is critical to system efficiency. - Chemical Processing Vital in preventing contamination in systems that handle toxic or hazardous materials. - HVAC Systems Utilized in heating and cooling systems to maintain proper fluid flow and prevent backflow.

Conclusion

In summary, non-return ball valves play a pivotal role in ensuring the efficient functioning of fluid systems across various industries. Their ability to prevent backflow and protect system integrity makes them indispensable in modern engineering applications. With their robust design and low maintenance requirements, non-return ball valves will continue to be a preferred choice for engineers and operators seeking reliable fluid control solutions.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024