11 月 . 02, 2024 11:46 Back to list

non return ball valve

Non-Return Ball Valve An Overview

Non-Return Ball Valve An Overview

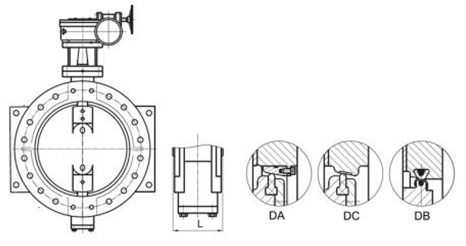

The design of a non-return ball valve is relatively straightforward. It typically consists of a spherical ball placed in a flow passage, held between two seats. When fluid flows in the designated direction, it pushes the ball away from the seat, allowing unrestricted flow. Conversely, if there is any attempt for the fluid to flow back, the ball is pushed against the seat, creating a tight seal that prevents reverse flow. This simple yet effective mechanism ensures that the integrity of the system is maintained.

non return ball valve

One of the key advantages of non-return ball valves is their ability to operate with minimal pressure drop. This characteristic is crucial in applications where maximizing flow efficiency is paramount. Additionally, these valves are generally low maintenance due to their robust design and reliable sealing capabilities. Unlike other types of check valves that may require springs or levers, non-return ball valves are less prone to wear and tear, which translates into longer service life.

Non-return ball valves are widely used across various industries, including oil and gas, water treatment, and manufacturing. In the oil and gas sector, they are crucial in pipelines to prevent backflow that can cause safety hazards and environmental concerns. In water treatment facilities, these valves help maintain proper flow in filtration and pumping systems, ensuring the process runs smoothly. Moreover, they are commonly found in HVAC systems to prevent reverse flow of refrigerants, which keeps the system efficient and safe.

In conclusion, the non-return ball valve plays a critical role in many fluid control systems. Its effective design and reliable performance make it an indispensable component that helps prevent backflow, ensuring the safety and efficiency of various applications. As industries continue to evolve and seek more efficient solutions, the non-return ball valve will undoubtedly remain a key player in fluid management technology. Understanding its function and applications is vital for engineers and technicians who aim to optimize system performance and longevity.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024