1 月 . 19, 2025 03:58 Back to list

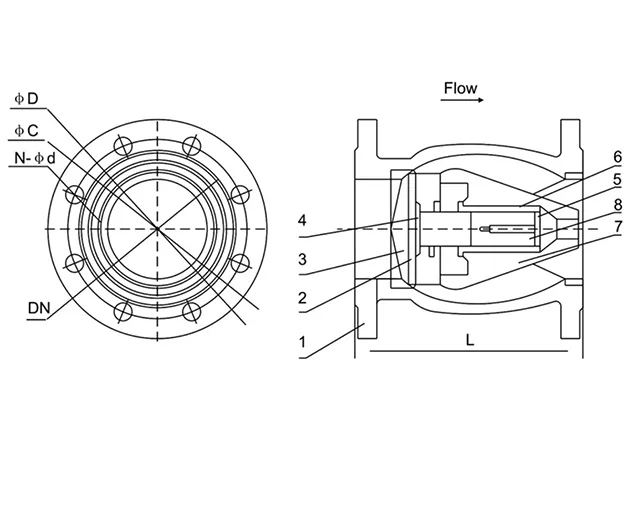

Single Plate Check Valve

The MSS swing check valve, a crucial component in various industrial applications, embodies the intricate intersection of engineering prowess and operational efficacy. Renowned for their ability to prevent backflow within pipelines, these valves play a pivotal role in ensuring the smooth and efficient operation of numerous systems, ranging from water treatment facilities to oil and gas transportation.

When installed correctly, MSS swing check valves can significantly improve the operational efficiency of a system. The absence of complex controls and easy maintenance requirements are additional benefits that reduce the total cost of ownership. Regular inspection protocols, as advised by industry standards, further reinforce the valve's operational integrity. Technicians are trained to detect early signs of wear, such as disc misalignment or hinge pin degradation, ensuring timely interventions that preempt potential system failures. In terms of authoritativeness, MSS swing check valves are backed by industry certifications which attest to their quality and safety. Compliance with standards such as ANSI, API, and ISO demonstrates the manufacturer's commitment to maintaining high production standards and product integrity. These certifications provide reassurance to end-users, validating that the valves have undergone rigorous testing to meet stringent operational criteria. Trustworthiness in selecting an MSS swing check valve is cemented through reliance on reputable manufacturers with a track record of excellence. User reviews and case studies provide insights into real-world applications, highlighting the valve's performance across diverse settings. Establishing a relationship with suppliers who offer comprehensive after-sales support ensures that technical assistance is readily available, fostering a sense of confidence in the product's reliability. In conclusion, the MSS swing check valve embodies a fusion of engineering innovation and practical application. Its robust construction, ease of maintenance, and certification-backed quality make it an invaluable asset across industries. For decision-makers and engineers alike, investing in a trusted and well-manufactured MSS swing check valve translates to enhanced operational efficiency, reduced risk of system failures, and an assurance of long-term reliability in fluid management systems.

When installed correctly, MSS swing check valves can significantly improve the operational efficiency of a system. The absence of complex controls and easy maintenance requirements are additional benefits that reduce the total cost of ownership. Regular inspection protocols, as advised by industry standards, further reinforce the valve's operational integrity. Technicians are trained to detect early signs of wear, such as disc misalignment or hinge pin degradation, ensuring timely interventions that preempt potential system failures. In terms of authoritativeness, MSS swing check valves are backed by industry certifications which attest to their quality and safety. Compliance with standards such as ANSI, API, and ISO demonstrates the manufacturer's commitment to maintaining high production standards and product integrity. These certifications provide reassurance to end-users, validating that the valves have undergone rigorous testing to meet stringent operational criteria. Trustworthiness in selecting an MSS swing check valve is cemented through reliance on reputable manufacturers with a track record of excellence. User reviews and case studies provide insights into real-world applications, highlighting the valve's performance across diverse settings. Establishing a relationship with suppliers who offer comprehensive after-sales support ensures that technical assistance is readily available, fostering a sense of confidence in the product's reliability. In conclusion, the MSS swing check valve embodies a fusion of engineering innovation and practical application. Its robust construction, ease of maintenance, and certification-backed quality make it an invaluable asset across industries. For decision-makers and engineers alike, investing in a trusted and well-manufactured MSS swing check valve translates to enhanced operational efficiency, reduced risk of system failures, and an assurance of long-term reliability in fluid management systems.

Share

Next:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024