10 月 . 05, 2024 12:05 Back to list

MSS Metal Seat Gate Valve Specifications and Applications Guide

MSS Metal Seat Gate Valve An Overview

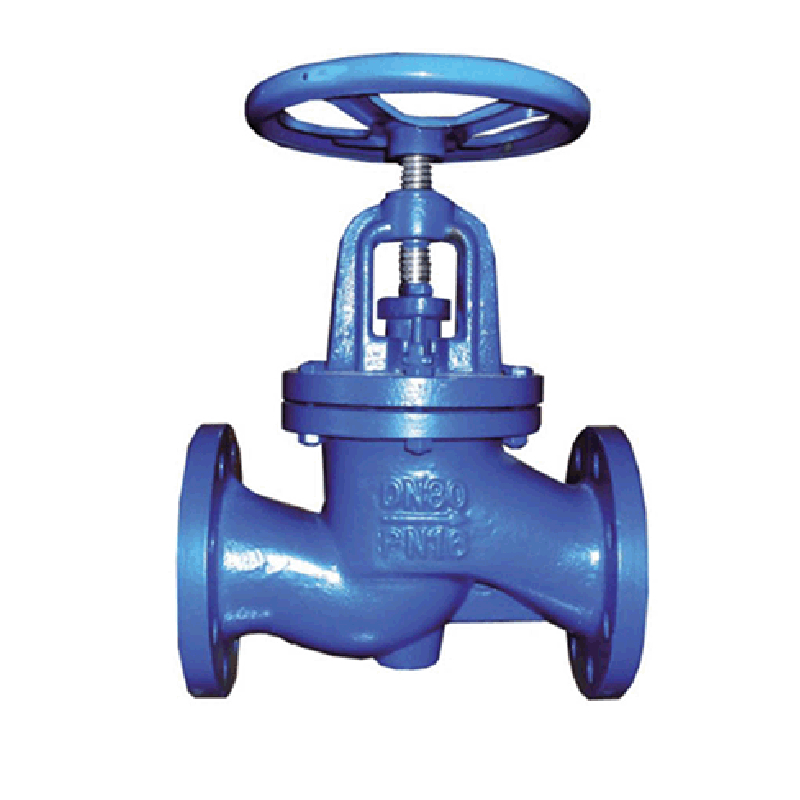

The MSS metal seat gate valve is a vital component in various industrial applications, known for its durability, reliability, and efficiency. As part of the broader category of gate valves, the metal seat variant is specifically designed to handle high-pressure and high-temperature situations where traditional seats may falter. This article explores the features, benefits, and applications of MSS metal seat gate valves, highlighting why they are essential in modern engineering.

Features of MSS Metal Seat Gate Valves

The MSS (Manufacturer’s Standardization Society) specifications outline stringent guidelines for gate valves, ensuring they meet the required industry standards. One of the defining characteristics of the metal seat gate valve is its construction. Unlike resilient seated valves that use softer materials like rubber or plastic for sealing, metal seat valves employ harder materials such as stainless steel or other alloys. This design allows them to withstand extreme conditions, making them suitable for demanding environments.

Additionally, these valves typically feature a wedge design that facilitates a full flow path, minimizing pressure drops across the valve. This is particularly beneficial in applications where fluid flow is critical, such as pipeline systems and oil and gas operations. Furthermore, the metal seat material enhances resistance to abrasion and impacts, which prolongs the lifespan of the valve.

Benefits of MSS Metal Seat Gate Valves

One of the primary advantages of using MSS metal seat gate valves is their longevity. The robust materials used in their construction allow them to endure wear and corrosion, traits that are essential for maintaining operational efficiency over time. Moreover, due to their design, these valves can be fully opened or closed without any obstruction, providing effective isolation of the flow path.

mss metal seat gate valve

Another benefit is their maintenance and repair simplicity. While all valves require maintenance, the metal seat design often leads to fewer issues over time compared to traditional soft-seated options. This reliability reduces downtime, which can be a significant cost factor in industrial operations.

Additionally, MSS metal seat gate valves are versatile and can be used in a wide range of applications, including water treatment facilities, chemical processing plants, power generation, and more. Their ability to function effectively in various medium types—liquids, gases, and steam—further emphasizes their adaptability.

Applications in Industry

The versatility of MSS metal seat gate valves makes them indispensable in many sectors. In the oil and gas industry, they are commonly used in pipeline systems to control flow and provide safety by isolating sections of the pipeline. In chemical manufacturing, these valves facilitate the handling of corrosive substances, thanks to their robust materials.

Moreover, in water and wastewater treatment facilities, the valves play a crucial role in managing inflows and outflows, ensuring that processes run smoothly and efficiently.

Conclusion

In summary, the MSS metal seat gate valve stands out as a durable and reliable choice for various industrial applications. With its robust construction and efficiency in high-pressure environments, it addresses the demands of modern engineering effectively. As industries continue to evolve, the importance of such valves will only continue to grow, cementing their place in the machinery that fuels our economy. Whether in energy, manufacturing, or environmental management, MSS metal seat gate valves are integral components that ensure effective operation and reliability across the board.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024