10 月 . 09, 2024 15:02 Back to list

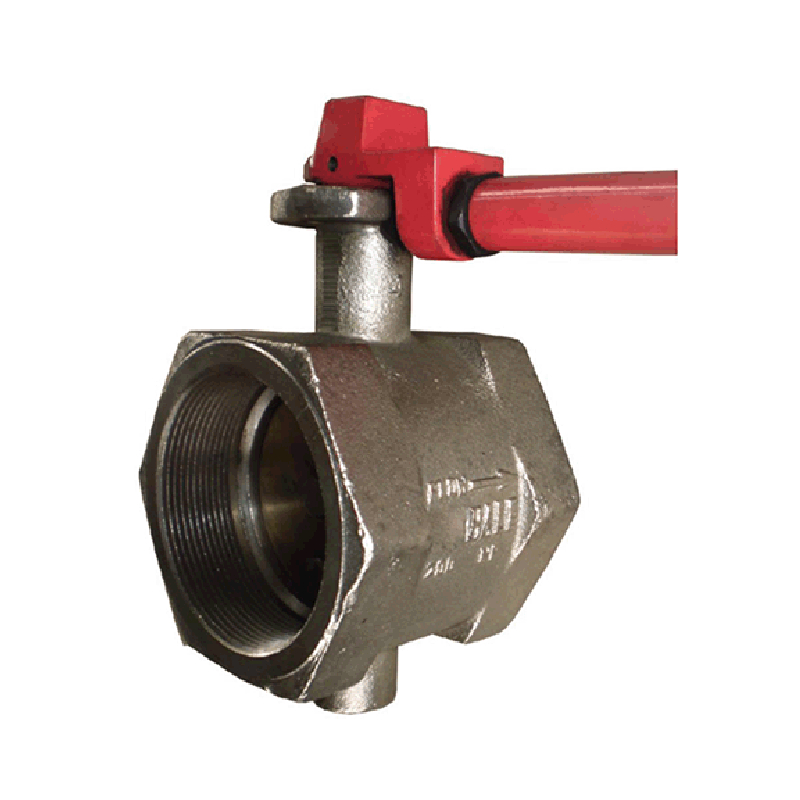

motorized knife gate valve

The Motorized Knife Gate Valve Revolutionizing Fluid Control in Industrial Applications

In the realm of fluid management and industrial processes, the significance of robust and reliable valves cannot be overstated. Among the various valve types available, the motorized knife gate valve has emerged as a key player, especially in applications requiring the handling of slurries, waste materials, and other challenging fluids. This article delves into the features, advantages, and applications of motorized knife gate valves, illustrating their indispensable role in modern industrial operations.

Understanding the Motorized Knife Gate Valve

A knife gate valve is designed for on-off control of flow in a piping system. Its unique structure features a thin, sharp-edged gate that can easily slice through materials, making it especially effective for slurries that contain solids. The addition of a motorized actuation system transforms this traditional valve into a dynamic component capable of automatic operation. The actuator, typically an electric motor, allows for precise control over the opening and closing of the valve, enhancing its functionality and efficiency.

Key Features

1. Efficient Flow Control Motorized knife gate valves facilitate quick and efficient flow control, allowing operators to manage the flow of liquids and slurries with minimal manual intervention. This is particularly advantageous in processes that demand frequent adjustments.

2. Durability These valves are constructed from robust materials, such as stainless steel or carbon steel, ensuring longevity and resistance to wear and tear, even in corrosive environments. Their design minimizes the risk of clogging and assures reliable operation.

3. Sealing Capability The gate design ensures excellent sealing properties when fully closed. By leveraging a self-cleaning feature, the knife gate valve prevents accumulated debris from obstructing the flow, maintaining optimal performance over time.

4. Automated Operation The integration of motorized actuators allows for remote operation and automatic system control. This not only reduces the need for manual labor but also enhances safety by keeping operators away from potentially hazardous environments.

5. Compact Design Motorized knife gate valves are typically more compact than other valve types, making them suitable for installations where space is limited. Their design also allows for easy maintenance, which is essential for minimizing downtime in industrial settings.

motorized knife gate valve

Advantages of Motorized Knife Gate Valves

The adoption of motorized knife gate valves offers several advantages

- Increased Productivity Automated operation leads to faster response times, reducing delays in production processes and increasing overall efficiency. - Enhanced Safety By minimizing manual intervention in potentially hazardous areas, these valves improve workplace safety.

- Reduced Maintenance Costs The durable construction and self-cleaning features of motorized knife gate valves lower the frequency of required maintenance, translating to cost savings over time.

- Versatility Suitable for various industries, including wastewater treatment, pulp and paper, mining, and food and beverage processing, motorized knife gate valves can be tailored to meet specific operational needs.

Applications

Motorized knife gate valves are widely used across various industries. In wastewater treatment facilities, they control the flow of sewage and sludge, ensuring efficient processing and environmental protection. In the pulp and paper industry, these valves are utilized to manage the flow of fibrous materials and chemicals. Additionally, in mining operations, they handle slurry transportation and mineral processing, demonstrating their versatility and reliability in demanding conditions.

Conclusion

In summary, the motorized knife gate valve is a quintessential component in fluid management and processing in numerous industrial applications. Its combination of durability, efficiency, and automation not only enhances operational productivity but also ensures safety and reliability. As industries continue to evolve, the adoption of advanced valve technologies like the motorized knife gate valve will play a critical role in meeting the challenges of modern fluid control.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024