10 月 . 06, 2024 08:12 Back to list

Durable Metal Seat Gate Valves for Reliable Fluid Control Solutions

Metal Seat Gate Valve An Overview

In industrial applications, the significance of reliable and efficient piping systems cannot be overstated. Among the various types of valves used for flow control, the metal seat gate valve stands out for its robust design and functionality. This article delves into the characteristics, advantages, and applications of metal seat gate valves, highlighting their importance in diverse industries such as oil and gas, water treatment, and power generation.

Understanding Metal Seat Gate Valves

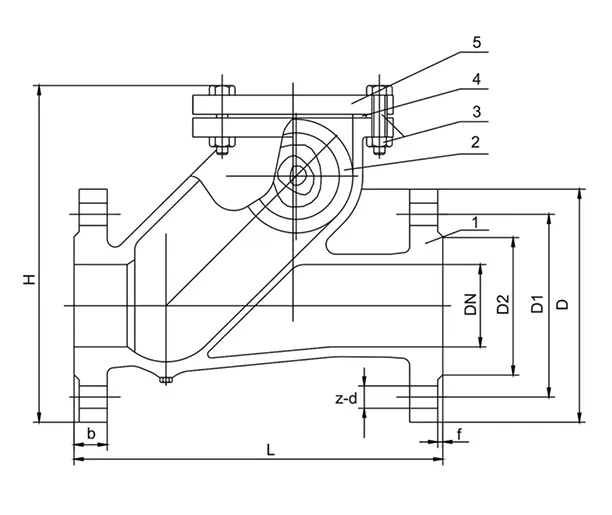

A gate valve is designed to allow or obstruct the flow of fluids through a piping system. It operates by lifting or lowering a wedge-shaped gate that fits into a seat, thereby either allowing the liquid to pass unhindered or sealing the flow completely. The distinguishing feature of a metal seat gate valve is the seat material, which is typically crafted from metal rather than softer materials like rubber or plastic. This choice provides enhanced durability and resilience against the high pressures and temperatures encountered in many industrial applications.

Key Features

1. Durability and Resistance The metal seating surface provides improved resistance to wear, corrosion, and high-temperature effects. This makes metal seat gate valves ideal for harsh environments where traditional seat materials might fail.

2. Low Friction Due to the design and material properties, metal seat gate valves generally exhibit lower friction when operated. This enables smoother opening and closing actions, which is essential for maintaining system efficiency and reducing wear over time.

3. Tight Sealing Metal seat designs ensure tighter sealing compared to traditional materials. This is particularly crucial in applications where leakage is unacceptable, such as in oil and gas pipelines where environmental safety is paramount.

4. Wide Range of Applications These valves can handle various fluids, including water, oils, gases, and steam, making them versatile for numerous applications across different sectors.

Advantages of Metal Seat Gate Valves

Metal seat gate valves offer several advantages that make them a preferred choice in many industrial settings

- Long Longevity Their resistance to wear and fatigue translates into a longer service life compared to softer seat materials. This longevity results in reduced maintenance costs and downtime, providing significant economic benefits.

metal seat gate valve

- High Temperature and Pressure Tolerance Metal seat gate valves can operate effectively at elevated temperatures and pressures, making them suitable for critical applications in power plants and chemical industries.

- Minimal Flow Restriction When fully open, these valves provide an unobstructed flow path, which minimizes pressure loss and enhances system efficiency.

- Versatile Installation They can be installed in either horizontal or vertical configurations, which offers flexibility in system design.

Applications

Metal seat gate valves are extensively used in various industries

- Oil and Gas In petroleum production and refining, metal seat gate valves offer reliable shut-off capabilities, ensuring operational safety and efficiency.

- Water Treatment These valves are utilized in water distribution systems to manage flow and prevent contamination by ensuring a tight seal.

- Chemical Processing In chemical plants, the ability to handle aggressive media at high temperatures makes metal seat gate valves indispensable.

- Power Generation They are employed in steam cycles of power plants, where durability under extreme conditions is essential.

Conclusion

In summary, metal seat gate valves play an essential role in modern industrial applications demanding reliability, safety, and efficiency. Their robust design, coupled with the advantages of metal seating, makes them a prime choice for a wide range of critical applications across various sectors. As industries seek to enhance operational efficiency while maintaining safety standards, the importance of metal seat gate valves will only continue to grow. Investing in quality metal seat gate valves not only promotes smooth operations but also contributes significantly to long-term cost savings and environmental protection.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024