11 月 . 04, 2024 11:31 Back to list

metal seat gate valve

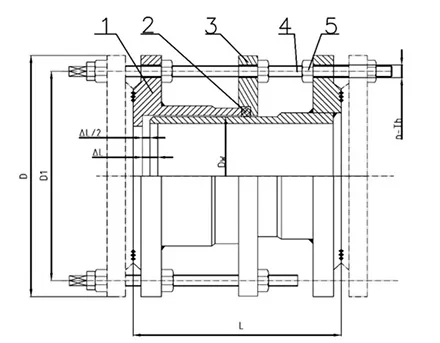

Understanding Metal Seat Gate Valves

Metal seat gate valves are essential components in various industrial applications, known for their reliability and durability. These valves are primarily used to control the flow of liquids and gases in pipelines, making them crucial in industries such as oil and gas, water treatment, and power generation.

One key feature of metal seat gate valves is their design, which allows for a straight-through flow path. This design minimizes pressure drops when the valve is fully open, ensuring efficient operation. The gate, or disc, of the valve is either raised or lowered into the flow path to open or close it. When fully opened, it allows for unobstructed flow, which is a significant advantage in applications requiring high flow rates.

The metal seat aspect refers to the valve’s seating arrangement, where the gate meets the valve body. Unlike soft-seated valves, which use materials like rubber or PTFE (Teflon) for sealing, metal seat valves utilize steel or other alloys. This construction provides superior wear resistance, making them suitable for applications involving abrasive fluids or high temperatures. The metal-to-metal contact ensures a tight seal, reducing the likelihood of leaks and extending the valve's lifespan.

metal seat gate valve

Moreover, metal seat gate valves can operate effectively under severe conditions, such as high pressure and extreme temperatures

. This durability makes them a preferred choice in demanding environments where reliability is paramount. In critical systems, such as those found in power plants or chemical processing facilities, these valves play a significant role in safeguarding operations and maintaining safety standards.Installation and maintenance of metal seat gate valves are relatively straightforward. Regular maintenance is essential to ensure optimal functioning, involving periodic inspections to detect wear and tear and lubricating moving parts as needed. Attention to these details can enhance the valve's performance and prevent unplanned downtimes.

In recent years, advancements in manufacturing technologies have allowed for the production of even more robust metal seat gate valves. Innovations such as improved alloys and precision machining contribute to better performance and longer service life.

In summary, metal seat gate valves stand out due to their reliability, durability, and efficiency in fluid control applications. Their ability to withstand harsh conditions and provide a reliable seal makes them indispensable in various industries. By understanding the capabilities and maintenance requirements of these valves, industries can ensure their systems operate smoothly and efficiently over time.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024