2 月 . 13, 2025 19:14 Back to list

Dismantling Joint

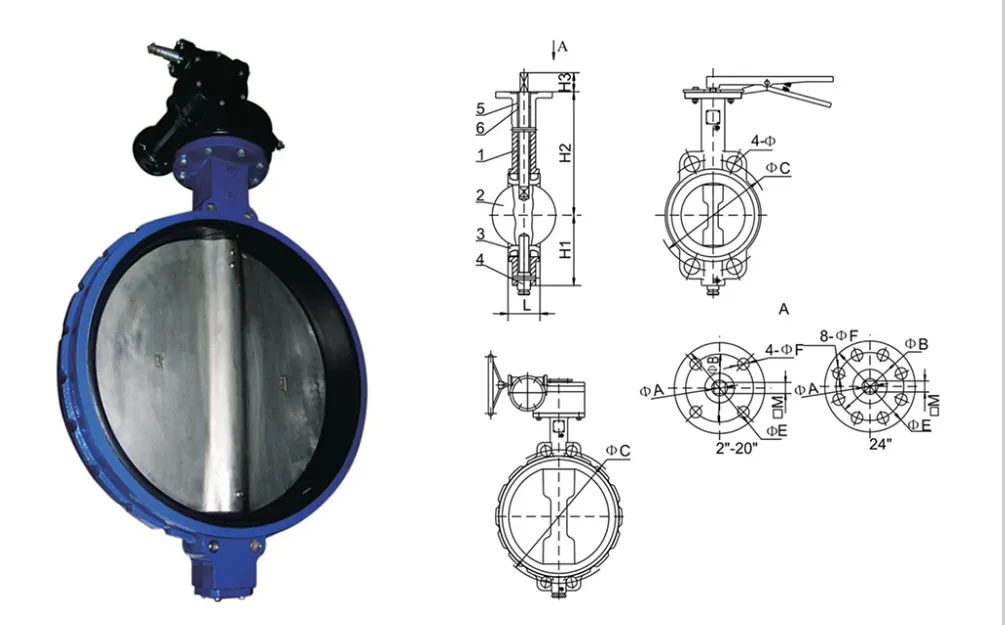

In the industrial field, the choice of valves is critical, with the lug type butterfly valve emerging as an industry favorite due to its versatile application and robust design. With decades of practical experience in fluid control systems, experts have consistently pointed out the unique advantages of utilizing this type of valve over others.

Moreover, the flow control precision offered by lug type butterfly valves is a testament to their engineering prowess. Various control options, including manual, electric, or pneumatic actuators, provide engineers the ability to tailor the valve operation to specific system requirements. This flexibility underscores the valve's authoritative status in applications requiring precise control and reliability. When considering trustworthiness, the lug type butterfly valve's track record speaks volumes. Tested and approved by industry standards, such as ISO and API, these valves have been proven reliable under demanding environments. Regular assessments and updates to the design by authoritative bodies ensure that today's butterfly valves exceed operational expectations while maintaining user safety and system integrity. Case studies further illustrate the practical benefits of using lug type butterfly valves. In numerous industrial scenarios, companies have reported enhanced system efficiency and reduced maintenance time by implementing these valves. The combination of easy usability, system reliability, and operational flexibility aligns with the goals of modern industrial operations seeking cost-effectiveness coupled with high performance. In conclusion, the lug type butterfly valve is not merely a component in a piping system but a strategically significant part of industrial processes. Its documented success across various sectors underscores its esteemed position among engineers and industry professionals. By aligning its design with unparalleled expertise and unwavering authority in valve technology, this type of valve continues to build trust among its users, proving its resilience and foresight in ever-evolving industrial demands.

Moreover, the flow control precision offered by lug type butterfly valves is a testament to their engineering prowess. Various control options, including manual, electric, or pneumatic actuators, provide engineers the ability to tailor the valve operation to specific system requirements. This flexibility underscores the valve's authoritative status in applications requiring precise control and reliability. When considering trustworthiness, the lug type butterfly valve's track record speaks volumes. Tested and approved by industry standards, such as ISO and API, these valves have been proven reliable under demanding environments. Regular assessments and updates to the design by authoritative bodies ensure that today's butterfly valves exceed operational expectations while maintaining user safety and system integrity. Case studies further illustrate the practical benefits of using lug type butterfly valves. In numerous industrial scenarios, companies have reported enhanced system efficiency and reduced maintenance time by implementing these valves. The combination of easy usability, system reliability, and operational flexibility aligns with the goals of modern industrial operations seeking cost-effectiveness coupled with high performance. In conclusion, the lug type butterfly valve is not merely a component in a piping system but a strategically significant part of industrial processes. Its documented success across various sectors underscores its esteemed position among engineers and industry professionals. By aligning its design with unparalleled expertise and unwavering authority in valve technology, this type of valve continues to build trust among its users, proving its resilience and foresight in ever-evolving industrial demands.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024