10 月 . 12, 2024 16:00 Back to list

lugged butterfly valve

The Lugged Butterfly Valve An Overview of Design and Applications

The lugged butterfly valve is an essential component in various industrial applications, known for its efficient flow control and reliability in both on-off and throttling functions. This type of valve is particularly versatile due to its unique design, which combines the features of standard butterfly valves with the additional support of lugged connections. This article explores the design characteristics, advantages, and applications of lugged butterfly valves.

Design Characteristics

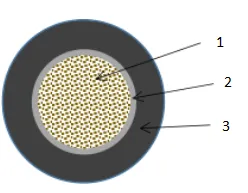

The lugged butterfly valve features a circular disc that rotates within the valve body to either restrict or allow the flow of fluid. The design includes two lugs, or protrusions, on either side of the valve body, which allow for easy mounting between two flanges. This lugged configuration eliminates the need for a separate valve body, making installation simpler and more cost-effective. The standard materials used in manufacturing these valves include stainless steel, cast iron, and various alloys, allowing them to withstand a wide range of temperatures and pressures.

One of the key components of the lugged butterfly valve is the disc. The disc can be constructed from a variety of materials, including rubber-coated options for corrosive applications, ensuring longevity and performance. The valve can be operated manually via a built-in handle or automatically using an actuator, making it adaptable for different operational needs.

Advantages of Lugged Butterfly Valves

1. Compact Design Lugged butterfly valves are generally more compact than their gate valve counterparts. This feature makes them ideal for applications where space is limited, such as in piping systems within industrial plants.

2. Light Weight The lightweight nature of these valves simplifies installation and reduces structural load on the piping system. This factor is particularly advantageous in applications where weight is a critical consideration.

4. Easy Maintenance The internal structure of a lugged butterfly valve makes maintenance straightforward. Many models allow for in-line servicing, meaning the valve can be inspected and repaired without needing to remove it from the pipeline.

lugged butterfly valve

5. Versatile Applications These valves can handle a wide range of fluids, including water, wastewater, chemicals, and gases. Their adaptability makes them suitable for various industries, including water treatment, chemical processing, and HVAC systems.

Applications of Lugged Butterfly Valves

Lugged butterfly valves find applications across diverse sectors due to their reliable performance and ease of use. Common applications include

1. Water Treatment Facilities They are widely used in water and wastewater treatment plants to regulate the flow of water during various processing stages.

2. Chemical Processing Plants Their ability to handle caustic and corrosive fluids makes lugged butterfly valves an ideal choice for chemical manufacturing processes.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these valves regulate air and water flow, contributing to the system's overall efficacy.

4. Food and Beverage Industry Hygienic designs of lugged butterfly valves make them suitable for applications within food processing, ensuring that production complies with health and safety standards.

5. Oil and Gas Industry They are reliable for isolating and controlling the flow of hydrocarbons, making them critical components in pipelines and refining processes.

Conclusion

The lugged butterfly valve stands out as a highly efficient and versatile component in the realm of flow control. Its robust design, coupled with the advantages of easy maintenance and cost-effectiveness, makes it suitable for a wide array of applications across various industries. As industries continue to evolve, the demand for effective and reliable flow regulation solutions will keep lugged butterfly valves at the forefront of engineering and design. Whether in water treatment, chemical processing, or HVAC systems, these valves will remain crucial for operational efficiency and effectiveness in fluid management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024