9 月 . 04, 2024 08:42 Back to list

lugged butterfly valve

Understanding Lugged Butterfly Valves A Comprehensive Overview

Lugged butterfly valves are critical components in various industrial applications, serving the essential purpose of regulating and controlling fluid flow. These valves are especially popular in sectors such as water treatment, chemical processing, and HVAC systems. Their design and functionality make them a preferred choice for many engineers and plant operators.

What is a Lugged Butterfly Valve?

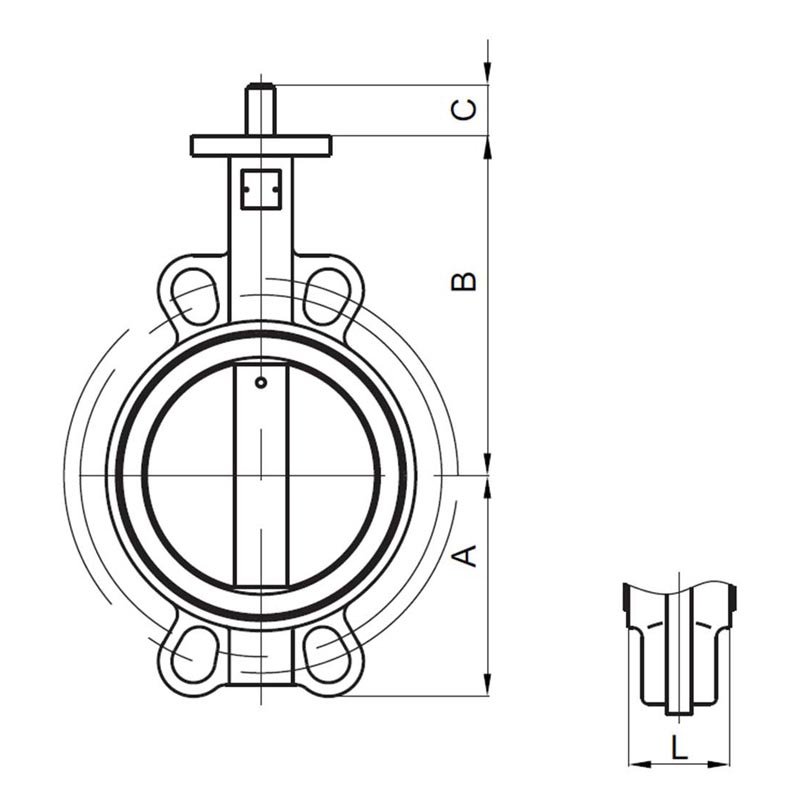

A lugged butterfly valve features a unique design characterized by its disc, which rotates on a shaft to control the flow of fluid through the valve. What distinguishes a lugged butterfly valve from its counterparts is the presence of lugs or threaded extensions on the body of the valve. These lugs enable the valve to be bolted directly between two flanges in a piping system, providing a secure and stable installation.

Features and Benefits

One of the standout features of lugged butterfly valves is their versatility

. They can be used in both isolation and throttling applications, making them suitable for a wide range of operational demands. Furthermore, the design minimizes pressure drop across the valve, which is an essential factor in maintaining system efficiency.Another significant advantage of lugged butterfly valves is their compact structure. This design not only saves space but also reduces the overall weight of the valve compared to other types, such as gate or globe valves. Additionally, the simple operation and minimal maintenance requirements of these valves make them a cost-effective solution over their lifespan.

lugged butterfly valve

Applications

Lugged butterfly valves are commonly used in a variety of industries. In water treatment facilities, they control the flow of water through various stages of processing, ensuring the efficient treatment and distribution of potable water. In chemical processing plants, these valves manage the flow of corrosive and viscous fluids, providing reliable sealing against leaks. Furthermore, in HVAC systems, they regulate airflow, contributing to energy efficiency in climate control.

Selection Considerations

When selecting a lugged butterfly valve, several factors must be considered. These include the type of fluid being handled, the temperature and pressure conditions of the system, and the required size of the valve. Additionally, the material of the valve is crucial, as it must withstand the specific chemical properties of the fluid and environmental conditions.

Conclusion

In conclusion, lugged butterfly valves are indispensable in modern industrial applications due to their unique features and adaptability. Their ability to provide reliable flow control while saving space and reducing weight makes them a valuable choice for engineers and operators alike. As industries continue to evolve, the importance of efficient and robust valve solutions like the lugged butterfly valve will undoubtedly grow, supporting the increasing demands for effective fluid management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024