10 月 . 10, 2024 21:37 Back to list

low pressure check valve

Understanding Low Pressure Check Valves Essentials and Applications

Low pressure check valves are critical components in various fluid systems, ensuring that fluid flows in one direction while preventing backflow. These valves play an essential role in maintaining system integrity and efficiency in numerous applications, from industrial processes to domestic plumbing. This article provides an overview of low pressure check valves, their mechanisms, applications, and best practices for installation and maintenance.

What is a Low Pressure Check Valve?

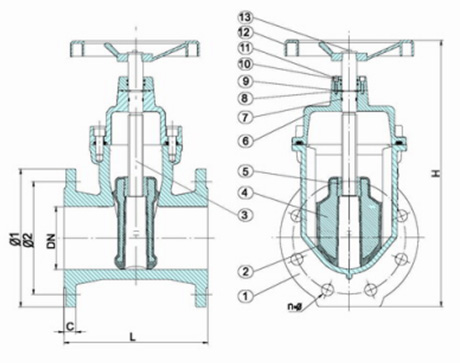

A check valve, also known as a one-way valve, is designed to allow fluid to flow through it in one direction only. Low pressure check valves are specifically engineered to operate effectively at lower pressure ranges. These valves prevent backflow, which can lead to contamination of fluid systems, damage to equipment, and operational inefficiencies.

Typically constructed from materials such as brass, stainless steel, or PVC, low pressure check valves are available in various designs, including spring-loaded and gravity-assisted models. The choice of design often depends on the specific application, the type of fluid being used, and the required performance characteristics.

Mechanism of Operation

The operation of a low pressure check valve is relatively simple. When fluid flows in the intended direction, it exerted pressure on the valve disc or ball, pushing it open and allowing the fluid to pass through. When the flow ceases or reverses, gravity and/or spring tension close the valve, sealing it to prevent backflow.

The response time and efficiency of a check valve can vary based on its design and the characteristics of the fluid. For example, spring-loaded check valves tend to react faster to changing pressure conditions compared to gravity-operated valves, making them suitable for applications where quick response is crucial.

Applications of Low Pressure Check Valves

Low pressure check valves are used across various industries, including

2. Heating and Cooling Systems In HVAC systems, low pressure check valves help maintain the direction of refrigerant or coolant flow, promoting efficient operation and preventing cross-contamination.

low pressure check valve

3. Pumping Applications In pumps, these valves are crucial for preventing backflow when the pump is off, maintaining prime and protecting the pump components.

4. Chemical Processing In chemical industries, low pressure check valves are used to control the flow of corrosive or hazardous materials, ensuring both safety and efficiency.

5. Aquaculture and Aquariums These valves prevent backflow of water, ensuring that the ecosystem remains balanced and that the water quality is maintained.

Best Practices for Installation and Maintenance

To ensure optimal performance of low pressure check valves, proper installation and maintenance are essential. Here are some best practices

- Correct Orientation Check valves must be installed according to the manufacturer’s specifications regarding orientation. Incorrect installation can lead to failure in preventing backflow.

- Avoiding Pressure Drops It is important to ensure that the valves are installed in areas where the pressure drop will be minimal. This helps maintain performance and reduces wear and tear.

- Regular Inspection Routine checks for wear, corrosion, and seal integrity can help detect potential issues early. This is especially important in aggressive environments where chemicals or varying temperatures may be present.

- Cleaning Keeping the valve clean from debris and sediment will help maintain its functionality and prolong its lifespan.

- Replace when Necessary Be proactive in replacing worn valves, as their failure can lead to significant downtime and costly repairs.

Conclusion

Low pressure check valves are essential devices in various fluid management systems. Their ability to prevent backflow and ensure the smooth operation of systems makes them indispensable in many applications. By understanding their functions, mechanisms, and best practices for maintenance, users can effectively leverage these valves to enhance system performance and reliability. Proper usage and care will assure that low pressure check valves serve their purpose efficiently for years to come.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024