9 月 . 15, 2024 09:06 Back to list

Low Pressure Check Valve - Essential Solutions for Fluid Control

Understanding Low Pressure Check Valves

Low pressure check valves play a crucial role in various fluid systems across multiple industries, ensuring the safe and efficient flow of liquids and gases. These valves are specifically designed to prevent backflow in a system, which can lead to contamination, inefficiency, and potential equipment damage. Understanding their function, application, and maintenance can significantly impact the performance of fluid systems.

What is a Low Pressure Check Valve?

A low pressure check valve is a type of one-way valve that allows fluid to flow in one direction while preventing it from flowing backward. This is essential in systems where backflow can cause issues, such as in water supply lines, drainage systems, and various industrial applications. Unlike pressure relief valves that are designed to release excess pressure, check valves are primarily concerned with flow direction and are typically not subjected to high-pressure conditions.

Applications of Low Pressure Check Valves

These valves find extensive use in both residential and industrial applications. In residential plumbing, they help to prevent the contamination of potable water supplies, ensuring that water flows in the correct direction. In HVAC systems, low pressure check valves help maintain system efficiency by preventing backflow of air, which can disrupt heating and cooling cycles.

In industrial settings, they are crucial in pumps and other fluid handling systems, where they prevent backflow that could damage equipment or disrupt processes. In chemical processing, low pressure check valves protect sensitive equipment from potentially harmful backflows, preserving both safety and efficiency in operations.

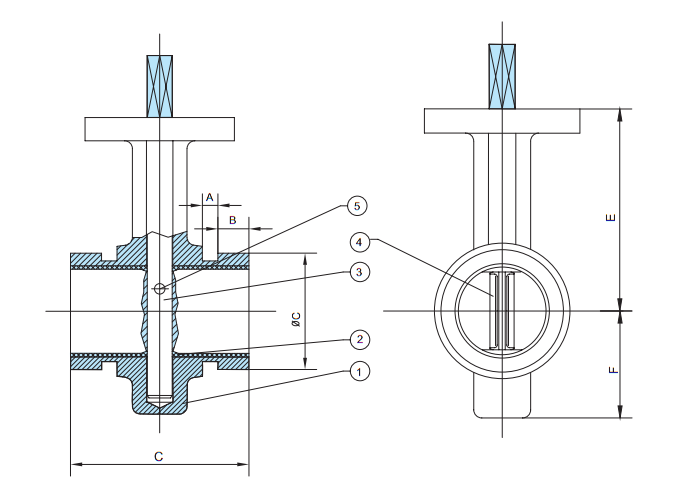

low pressure check valve

Types of Low Pressure Check Valves

There are several types of low pressure check valves, each with unique features tailored to specific applications. Common types include

1. Ball Check Valve Utilizes a ball to block reverse flow, ideal for low-pressure applications. 2. Swing Check Valve Features a swinging disc that opens and closes in response to flow conditions, suitable for larger pipelines. 3. Lift Check Valve Uses a disc that lifts off its seat when fluid flows in the correct direction, commonly used in smaller applications.

Choosing the right type of check valve depends on the specific requirements of the system, including flow rate, pressure conditions, and the nature of the fluid being transported.

Maintenance Considerations

Maintaining low pressure check valves is essential for ensuring their proper function. Regular inspections should be conducted to check for signs of wear, corrosion, or blockage. Proper installation is also crucial; installing the valve in the correct orientation is vital for its performance. Additionally, cleaning the valve periodically can help remove any debris that may impede its operation.

In conclusion, low pressure check valves are vital components in fluid systems that ensure proper flow direction and prevent backflow. Their application spans various industries, from residential plumbing to complex industrial processes. By understanding their function, types, and maintenance requirements, operators can optimize their systems and prevent potential issues caused by backflow. Proper deployment and care of these valves not only enhance the efficiency of fluid systems but also extend the lifespan of other connected equipment.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024