12 月 . 03, 2024 17:33 Back to list

long stem gate valve

Understanding Long Stem Gate Valves Functionality and Applications

Gate valves are widely recognized as essential components in fluid control systems. Among the various types of gate valves available in the market, the long stem gate valve stands out due to its distinctive design and functionality. This article delves into the structure, working principles, advantages, and applications of long stem gate valves.

Definition and Structure

A long stem gate valve is a type of valve that utilizes a long, elongated stem to operate the gate mechanism, which controls the flow of fluids in a pipeline. Unlike standard gate valves, which possess a shorter stem that is often directly attached to the valve body, the long stem design features an extended stem that provides greater accessibility and better control. The stem’s length allows for the manual operation of the valve from a distance, making it ideal for underground or hard-to-reach installations.

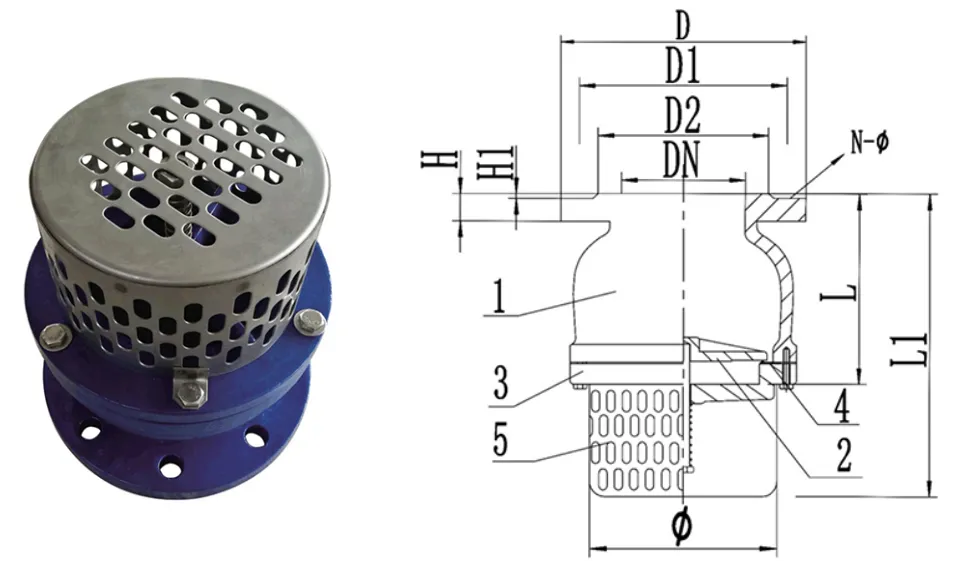

The main components of a long stem gate valve include the valve body, the gate (or disc), the long stem, and the handwheel or actuator used to operate the valve. The valve body is typically made of durable materials such as cast iron, stainless steel, or bronze, capable of withstanding various pressure and temperature conditions. The gate is positioned within the valve body and can move up and down to either obstruct or allow fluid flow.

Working Principle

The operation of a long stem gate valve is relatively straightforward. When the handwheel is turned in a clockwise direction, the stem ascends and lifts the gate out of the fluid flow path, hence allowing the fluid to pass through the valve. Conversely, when the handwheel is turned counterclockwise, the gate is lowered back into the flow path, effectively sealing the valve and stopping fluid movement.

One of the key advantages of this design is that, when fully opened, long stem gate valves provide minimal resistance to flow, making them suitable for applications requiring a straight-through pathway

. This is especially important in systems where fluid dynamics must remain efficient.Advantages of Long Stem Gate Valves

1. Accessibility The long stem design allows operators to control the valve from a distance, which is particularly beneficial in environments where valves are located underground, in pits, or in hazardous locations.

long stem gate valve

2. Minimal Flow Resistance When fully open, the valve allows for unobstructed fluid flow, reducing pressure drops and improving system efficiency.

3. Durability Made from robust materials, long stem gate valves are built to withstand extreme conditions, including high pressures and corrosive environments, ensuring long service life.

4. Versatility These valves can be used in various applications, including water supply systems, oil and gas pipelines, and industrial processes.

5. Low Maintenance The simple design often results in fewer maintenance requirements, compared to more complex valve types.

Applications

Long stem gate valves are utilized across multiple sectors. In water treatment facilities, they control the flow of water through pipelines, ensuring proper operation of the treatment process. In the oil and gas industry, they manage the flow in pipelines where safety and effective control are paramount. Additionally, they are used in irrigation systems, power plants, and chemical processing facilities.

Furthermore, long stem gate valves are crucial in wastewater management systems, where they help regulate the flow of wastewater through treatment plants. Their ability to be operated remotely contributes to safety, as operators can maintain control without needing to be in potentially hazardous environments.

Conclusion

In summary, long stem gate valves are vital devices in fluid control systems, combining efficiency, accessibility, and durability. Their unique design not only facilitates easier operation but also ensures minimal resistance to fluid flow, making them indispensable in various industrial applications. As industries continue to seek more effective solutions for fluid management, the role of long stem gate valves will likely become more critical in enhancing operational efficiency and safety. Understanding their significance can help professionals across various fields make informed decisions regarding their use and maintenance in fluid control applications.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024