9 月 . 10, 2024 23:01 Back to list

Long Stem Gate Valve - High Performance & Durability

Understanding Long Stem Gate Valves A Comprehensive Overview

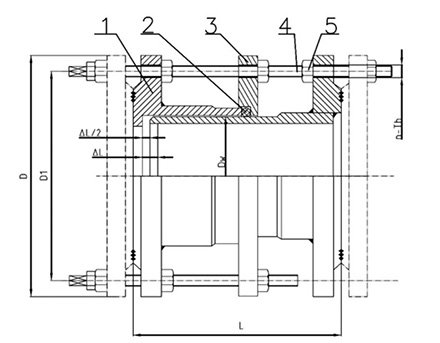

Long stem gate valves are essential components widely used in various industrial applications. Their design features an elongated stem that provides greater leverage and ease of operation, making them particularly suitable for areas where manual handling is necessary. This article will delve into the characteristics, advantages, and applications of long stem gate valves.

Gate valves, in general, are designed to either allow or block the flow of fluid. They work by raising or lowering a gate within the valve body, providing a straightforward on/off control. The long stem design enhances the valve's functionality, allowing operators to easily reach the handwheel or actuator, especially in applications where space constraints are a concern. This feature is particularly advantageous in underground installations or large machinery where direct access is limited.

One of the significant advantages of long stem gate valves is their ability to maintain a tight seal when closed

. The design minimizes the chances of leakage, which is crucial in applications involving hazardous materials or high-pressure systems. Furthermore, these valves are typically constructed from robust materials such as stainless steel, cast iron, or bronze, ensuring durability and resistance to corrosion, even in harsh environments.long stem gate valve

The long stem design also contributes to better thermal expansion management. In high-temperature applications, the extended stem allows for thermal expansion of the valve components without affecting the overall sealing capability. This characteristic is particularly important in industries such as oil and gas, chemical processing, and power generation, where temperature fluctuations are common.

In terms of installation and maintenance, long stem gate valves offer significant benefits. The extended stem can be easily inspected and serviced without the need to remove the valve from the pipeline. This ease of maintenance translates to reduced downtime and operational costs, making it a preferred choice for many facility managers and engineers.

Applications for long stem gate valves are diverse. They are commonly found in water treatment plants, oil refineries, chemical plants, and power plants, where reliable flow control is paramount. Additionally, their versatility allows them to be utilized in both high and low-pressure systems, making them a staple in various industrial setups.

In conclusion, long stem gate valves play a crucial role in maintaining operational efficiency across numerous industries. Their unique design, coupled with their reliability and ease of use, make them indispensable components in fluid control systems. As industries continue to evolve and expand, the demand for efficient and effective valve solutions, like long stem gate valves, will undoubtedly remain significant.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024