10 月 . 14, 2024 12:23 Back to list

lined check valve

Understanding Lined Check Valves Essential Components for Fluid Systems

Lined check valves are critical components in various fluid handling systems, designed to allow fluid flow in one direction while preventing backflow. These valves are especially valuable in applications involving corrosive or abrasive materials, where standard metal valves may suffer from wear and tear or chemical degradation.

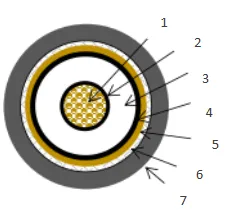

Construction and Materials

The primary feature of lined check valves is their protective lining. Typically made from materials such as rubber, PTFE (polytetrafluoroethylene), or other thermoplastics, the lining acts as a barrier against corrosive substances and abrasive particles. This protective layer not only extends the valve's lifespan but also maintains the integrity of the fluid being transported. The body of lined check valves is usually constructed from robust materials like carbon steel or stainless steel, ensuring durability and reliability under varying pressure and temperature conditions.

Operating Principle

The functioning of a lined check valve revolves around a simple yet effective mechanism. When fluid flows in the designated direction, it acts upon a disc or ball inside the valve, lifting it off its seat and allowing passage. Conversely, if the flow direction reverses, the disc or ball seals against the seat, thereby preventing backflow. Some lined check valves incorporate spring mechanisms to assist the closing action, ensuring a swift shut-off even under low-pressure conditions.

lined check valve

Applications

Lined check valves find extensive application across diverse industries such as chemical processing, oil and gas, water treatment, and HVAC systems. Their ability to handle challenging fluids, including acids, bases, and slurries, makes them indispensable in environments where equipment reliability is paramount. For instance, in chemical fluid systems, the use of lined check valves helps in safeguarding pumps and other components from the detrimental effects of backflow, thereby enhancing operational efficiency.

Advantages

The advantages of lined check valves are manifold. First, their protective lining significantly reduces maintenance costs by minimizing wear and prolonging valve life. Second, they help ensure system integrity by preventing backflow, which can lead to contamination and operational disruptions. Moreover, their versatility allows them to be tailored to suit specific operational conditions, accommodating various sizes, materials, and pressure ratings.

Conclusion

In summary, lined check valves provide a robust and reliable solution for managing fluid flow in a wide range of applications. Their unique construction, featuring protective linings, along with their simple operating principles, make them essential components in ensuring efficient and safe fluid systems. As industries continue to evolve, the demand for lined check valves is expected to rise, driven by the increasing need for reliability and durability in handling complex fluid dynamics. Understanding the benefits and functional characteristics of these valves can assist engineers and professionals in making informed decisions that optimize system performance and longevity.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024