10 月 . 08, 2024 22:59 Back to list

Lined Butterfly Valve Solutions for Efficient Flow Control and Reduced Corrosion Risks

Understanding Lined Butterfly Valves

Lined butterfly valves are critical components in various industries, particularly in processes involving corrosive fluids, slurries, or abrasive materials. Designed for flow regulation and on-off capabilities, these valves are characterized by a disc that rotates around a central axis. Their unique design allows for efficient control of fluid flow while minimizing pressure loss.

The primary feature that distinguishes lined butterfly valves from standard butterfly valves is the protective lining. This lining, typically made from materials like PTFE (polytetrafluoroethylene) or other elastomers, forms a barrier between the valve body and the fluid being handled. This is particularly important in applications where the fluid may cause corrosion or erosion to the valve components.

One of the key advantages of lined butterfly valves is their ability to handle aggressive chemicals and media, making them indispensable in industries such as chemical manufacturing, pulp and paper, and wastewater treatment. The liners not only extend the valve's lifespan but also ensure reliable performance by preventing leaks and reducing maintenance needs.

lined butterfly valve

The operational efficiency of lined butterfly valves is another significant factor. They are lightweight and compact, allowing for easy installation in tight spaces. Their actuator mechanisms can be manual, pneumatic, or electric, providing flexibility in automation and remote control applications. This versatility makes them suitable for a wide range of operational demands.

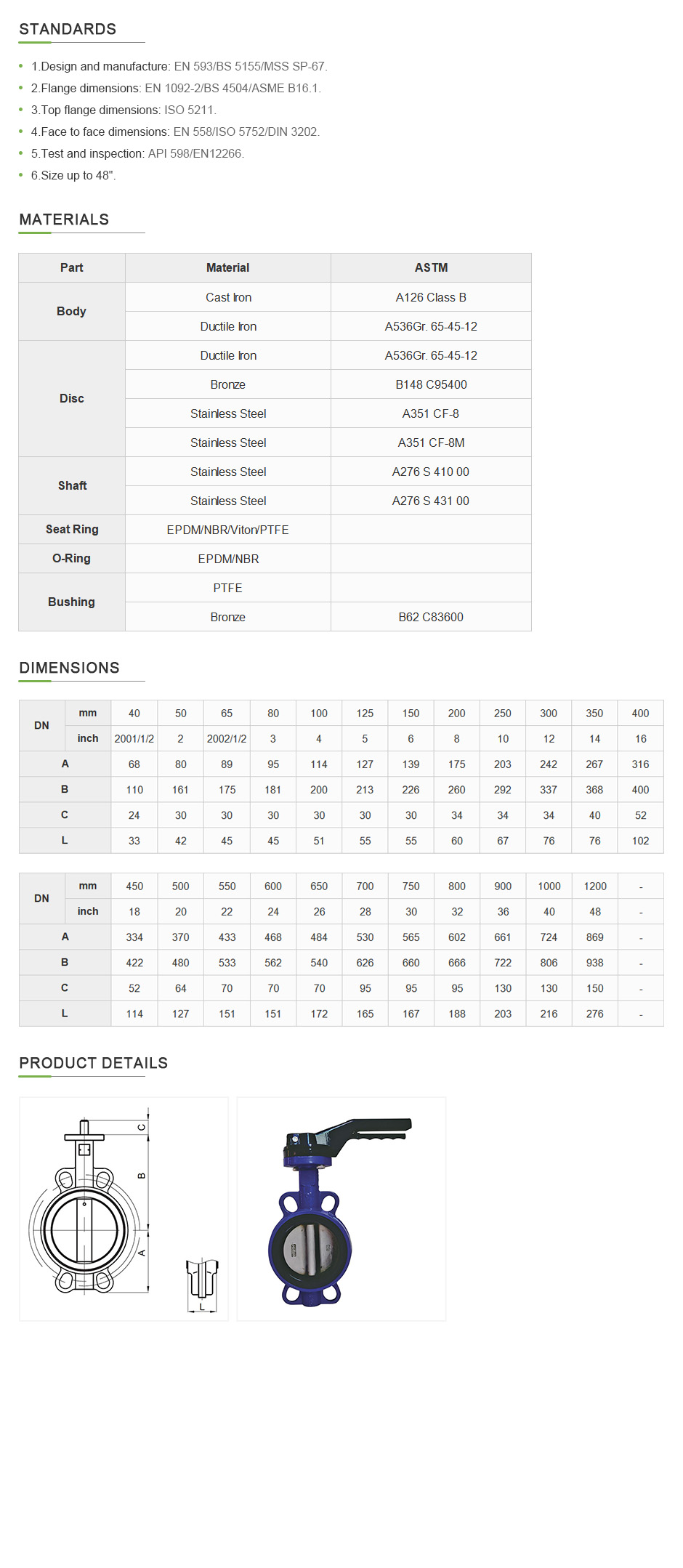

In terms of design, lined butterfly valves come in various configurations, including wafer-style and flanged types. The selection of the valve type often depends on the specific requirements of the piping system, including pressure ratings, sizes, and material compatibility. Additionally, the choice of lining material should match the chemical properties of the media to ensure optimal performance and safety.

While lined butterfly valves offer several benefits, it is essential to consider proper installation and maintenance practices. Ensuring that the valve is installed correctly in alignment with the piping system can prevent issues such as uneven wear or premature failure. Regular inspections and maintenance checks are crucial in identifying potential problems early, allowing for timely interventions that can save costs in the long run.

In conclusion, lined butterfly valves play a vital role in various industrial applications by providing robust solutions for fluid control. Their specialized design and protective linings make them ideal for handling harsh materials while maintaining operational efficiency. As industries continue to evolve, the demand for reliable and durable flow control mechanisms like lined butterfly valves will undoubtedly remain strong, reaffirming their significance in modern engineering.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024