10 月 . 17, 2024 01:35 Back to list

Optimizing Flow Control with Lined Butterfly Valves for Enhanced Performance and Durability

The Lined Butterfly Valve An Essential Component for Fluid Control

The modern industrial landscape relies heavily on efficient fluid control systems, and one of the unsung heroes of these systems is the lined butterfly valve. This valve type plays a crucial role in various applications, including chemical processing, water treatment, and power generation. With its unique design and features, the lined butterfly valve offers significant advantages over traditional valve types, making it an essential component in many industries.

Understanding the Lined Butterfly Valve

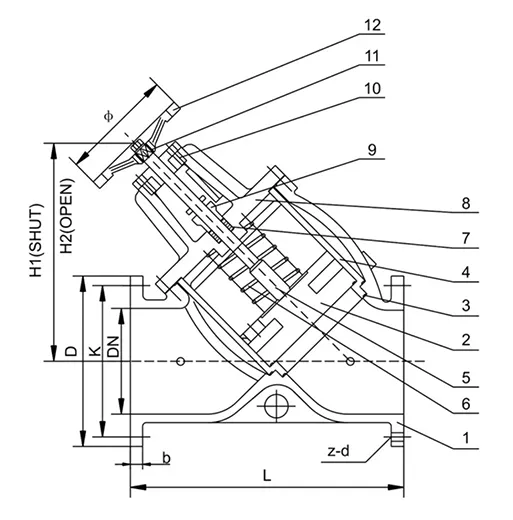

A butterfly valve consists of a circular disc or blade that is mounted on a rotating shaft. When the shaft is turned, the disc either opens or closes the flow of fluid through the pipe. What sets lined butterfly valves apart is the lining material that coats the valve body and disc. This lining is typically made from materials such as PTFE (polytetrafluoroethylene) or other rubber compounds, which enhance the valve’s resistance to corrosive substances and high temperatures.

Key Benefits

1. Corrosion Resistance The lining material is designed to withstand harsh chemicals and corrosive media, making lined butterfly valves particularly suitable for industries such as petrochemicals and pharmaceuticals. This resistance not only extends the lifespan of the valve but also ensures the integrity of the system it operates within.

2. Low Torque Requirements The streamlined design of the butterfly disc provides minimal resistance to fluid flow, resulting in lower torque requirements when operating the valve. This characteristic allows for easier manual or automated operation, reducing wear and tear on the actuator.

3. Lightweight and Compact Design Compared to other valve types, lined butterfly valves are lightweight and take up less space. This feature is particularly beneficial in environments with limited space and allows for easier installation and maintenance.

lined butterfly valve

4. Versatile Applications Lined butterfly valves can handle a wide range of temperatures and pressures. They are suitable for both on-off and throttling applications, making them versatile components in different fluid control scenarios.

5. Cost-Effective Although the initial investment might be higher compared to standard valves, the longevity and low maintenance requirements of lined butterfly valves can lead to cost savings in the long run. Their efficient performance reduces the likelihood of leaks and system failures, minimizing expensive downtime.

Installation and Maintenance

Proper installation and maintenance of lined butterfly valves are essential to maximize their performance and longevity. Before installation, it is important to ensure that the valve is compatible with the specific fluid and conditions of the system. During operation, regular inspections should be conducted to check for wear on the lining and the sealing surfaces.

Cleaning the valve, especially when handling viscous or particulate-laden fluids, can prevent clogging and maintain optimal performance. In case of any issues, it’s crucial to address them promptly to avoid compromising the overall system efficiency.

Conclusion

In summary, lined butterfly valves offer numerous advantages that make them indispensable in fluid control applications across various industries. Their corrosion resistance, low torque requirements, and compact design provide significant performance benefits, while their versatility allows them to be used in diverse conditions. As industries continue to evolve, the demand for efficient and reliable fluid control solutions will only increase, further solidifying the role of lined butterfly valves as a critical component in modern infrastructure. Investing in high-quality lined butterfly valves can lead to enhanced operational efficiency, reduced downtime, and ultimately greater profitability for organizations that rely on effective fluid management.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024