2 月 . 10, 2025 12:26 Back to list

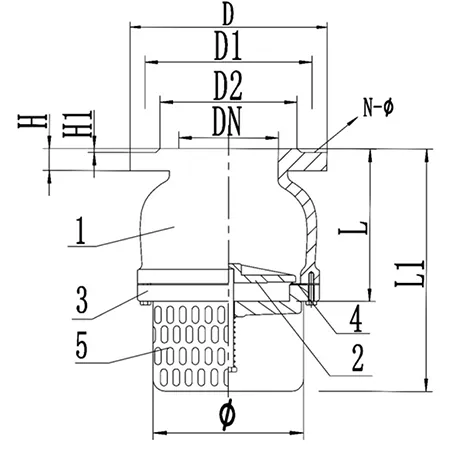

Foot Valve

Lever operated butterfly valves have become an essential component in various industries due to their efficiency, reliability, and ease of operation. This versatile valve is engineered to handle a wide range of applications—from water treatment and chemical processing to HVAC systems and fire protection services. Known for their simplistic yet effective design, lever operated butterfly valves offer a multitude of benefits that cater to diverse industrial needs.

Trustworthiness in these valves is further emphasized by their performance in critical applications, such as fire protection systems. Regulatory bodies often mandate the use of high-performance valves to ensure safety and reliability. Lever operated butterfly valves meet these stringent criteria by providing a secure seal and dependable operation under extreme conditions. Their ability to function effectively in emergency scenarios without failure underscores the trust clients place in these valves as pivotal assets in their operations. In addition to the mechanical and operational benefits, the cost-effectiveness of lever operated butterfly valves cannot be overstated. Their manufacturing process often incurs lower costs compared to other types of valves, such as globe or gate valves. This affordability, combined with their robust performance and low maintenance needs, makes them an appealing choice for budget-conscious projects. Businesses seeking to optimize their operational expenditures turn to these valves as a pragmatic solution without compromising on quality or reliability. For sectors aiming to integrate environmental sustainability into their operational framework, lever operated butterfly valves offer a greener solution. Their efficient flow control reduces energy consumption by minimizing the power required to open and close the valve. This energy efficiency contributes to a reduction in the overall carbon footprint, aligning with corporate sustainability goals and enhancing the valve's appeal to environmentally conscious industries. In summary, lever operated butterfly valves represent a fusion of efficiency, reliability, and versatility. Their space-efficient design, adaptability to various materials, and cost-effectiveness make them a preferred choice across diverse industrial applications. With a track record of dependable performance even in critical conditions, these valves continue to uphold their reputation as authoritative and trustworthy components in modern industry. As industries advance, the demand for these valves is set to grow, driven by their indispensable role in ensuring seamless and optimal operational performance.

Trustworthiness in these valves is further emphasized by their performance in critical applications, such as fire protection systems. Regulatory bodies often mandate the use of high-performance valves to ensure safety and reliability. Lever operated butterfly valves meet these stringent criteria by providing a secure seal and dependable operation under extreme conditions. Their ability to function effectively in emergency scenarios without failure underscores the trust clients place in these valves as pivotal assets in their operations. In addition to the mechanical and operational benefits, the cost-effectiveness of lever operated butterfly valves cannot be overstated. Their manufacturing process often incurs lower costs compared to other types of valves, such as globe or gate valves. This affordability, combined with their robust performance and low maintenance needs, makes them an appealing choice for budget-conscious projects. Businesses seeking to optimize their operational expenditures turn to these valves as a pragmatic solution without compromising on quality or reliability. For sectors aiming to integrate environmental sustainability into their operational framework, lever operated butterfly valves offer a greener solution. Their efficient flow control reduces energy consumption by minimizing the power required to open and close the valve. This energy efficiency contributes to a reduction in the overall carbon footprint, aligning with corporate sustainability goals and enhancing the valve's appeal to environmentally conscious industries. In summary, lever operated butterfly valves represent a fusion of efficiency, reliability, and versatility. Their space-efficient design, adaptability to various materials, and cost-effectiveness make them a preferred choice across diverse industrial applications. With a track record of dependable performance even in critical conditions, these valves continue to uphold their reputation as authoritative and trustworthy components in modern industry. As industries advance, the demand for these valves is set to grow, driven by their indispensable role in ensuring seamless and optimal operational performance.

Share

Prev:

Latest news

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024