10 月 . 30, 2024 21:40 Back to list

lever operated butterfly valve

Understanding Lever Operated Butterfly Valves A Comprehensive Overview

Butterfly valves are vital components in various industries, utilized for regulating and isolating fluid flow. Among the different types of butterfly valves, the lever-operated variant stands out for its simplicity and effectiveness. This design incorporates a lever mechanism that facilitates manual operation, making it particularly popular in applications where quick adjustments are necessary.

Functionality and Design

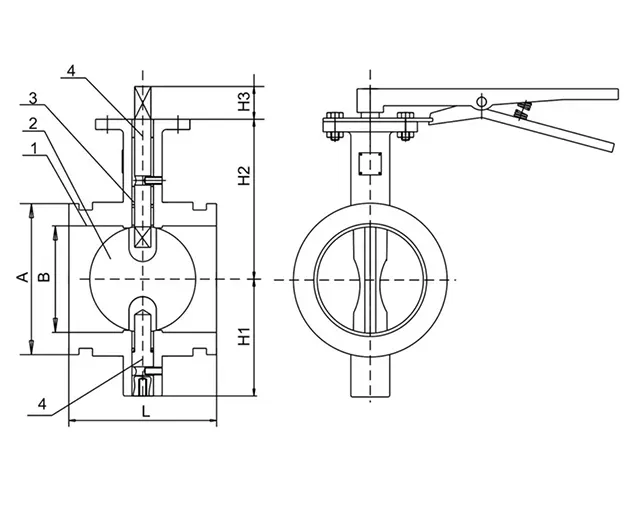

A lever operated butterfly valve consists of a circular disc mounted on a rotating shaft. When the lever is turned, the disc rotates, either permitting or obstructing the flow of fluid through the pipe. This mechanism allows for rapid open or close operations. The design often includes a handle that provides a mechanical advantage, enabling operators to exert the necessary force to move the valve with ease.

The leverage system not only enhances operational efficiency but also reduces the physical exertion required to operate the valve. This is especially beneficial in situations where valves are frequently adjusted or in hard-to-reach locations. Lever-operated butterfly valves are available in various sizes and materials, accommodating different pressure ratings and ensuring compatibility with diverse media, including water, air, and corrosive chemicals.

Applications in Industry

These valves are extensively used in sectors such as water treatment, chemical processing, and HVAC systems. In wastewater management, for instance, lever-operated butterfly valves control the flow and direction of sewage and stormwater, ensuring efficient treatment processes. In chemical manufacturing, these valves regulate the flow of various substances, minimizing the risk of leaks and ensuring safety standards are met.

lever operated butterfly valve

Moreover, in heating, ventilation, and air conditioning (HVAC) systems, lever-operated butterfly valves play a crucial role in maintaining optimal airflow and pressure levels. Their quick operation allows for immediate response to system demands, enhancing overall energy efficiency.

Advantages and Benefits

One of the primary advantages of lever-operated butterfly valves is their ease of use. Operators can quickly and effortlessly open or close the valve, which is critical in emergency situations where swift action is required. Additionally, these valves generally have a compact design, which saves space compared to traditional gate valves, making them suitable for tight installations.

Another significant benefit is their cost-effectiveness. The simple construction of butterfly valves makes them less expensive to manufacture and maintain. Moreover, since there are fewer moving parts, the risk of mechanical failure is reduced, leading to lower long-term operational costs.

Conclusion

In summary, lever-operated butterfly valves are an integral part of many industrial systems, offering practicality, efficiency, and cost savings. Their straightforward design allows for quick and easy operation, making them ideal for situations requiring frequent adjustments. As industries continue to evolve, the role of butterfly valves—especially those operated by levers—will remain crucial in ensuring smooth and effective fluid management across various applications. Understanding their functionality and advantages enables professionals to make informed decisions regarding valve selection and operation, ultimately optimizing system performance.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024