10 月 . 16, 2024 10:24 Back to list

lever operated butterfly valve

Lever Operated Butterfly Valve An Overview

A lever-operated butterfly valve is a crucial component in fluid control systems, widely utilized in various industries such as water treatment, oil and gas, chemical processing, and HVAC systems. Known for its simplicity, efficiency, and reliability, this type of valve is engineered to regulate the flow of liquids and gases with minimal energy consumption and maintenance requirements.

Design and Operation

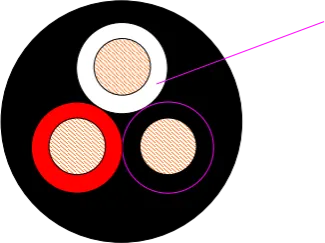

The butterfly valve consists of a disc or a plate that pivots on a shaft, allowing for quick and efficient control of the flow path. When the lever is turned, it rotates the disc into or out of the flow, either blocking or allowing passage. This design makes the butterfly valve ideal for applications requiring frequent opening and closing of the valve, as it can quickly shift from a fully open to a fully closed position, or vice versa.

The lever mechanism is a manual operation system, giving operators direct control over the valve’s position. This can be particularly beneficial in environments where automation is not feasible or desired. The ease of use associated with manual lever operation also ensures that personnel can react swiftly to changes in operation requirements or emergency situations.

Advantages

One of the significant advantages of lever-operated butterfly valves is their compact design, which allows for installation in tight spaces without compromising functionality. Moreover, these valves are relatively lightweight compared to other types, reducing the structural load on piping systems.

lever operated butterfly valve

Another notable benefit is the cost-effectiveness of butterfly valves. Their design leads to lower manufacturing and maintenance costs compared to other valve types, such as gate or globe valves. Additionally, their low torque requirements mean that less energy is needed to operate the valve, further contributing to operational efficiency.

Applications

Lever-operated butterfly valves are versatile and can be found in a wide array of applications. They are commonly used in water distribution systems, where quick control of flow is critical. In the chemical industry, these valves handle various fluids, in both low and high-pressure environments, due to their resilience to corrosion and wear.

In HVAC systems, they help regulate air flow and maintain appropriate temperature levels within buildings. This adaptability across different sectors underscores why they are a preferred choice for many engineers and system designers.

Conclusion

In summary, lever-operated butterfly valves represent a balance of simplicity, efficiency, and cost-effectiveness in fluid handling systems. Their manual operation provides reliability and immediate response in critical situations, while their compact design ensures versatility across various applications. As industries continue to evolve, the importance of such valves in fluid control processes cannot be overstated. Whether for water management or chemical processing, the lever-operated butterfly valve remains an essential tool in maintaining system integrity and efficiency.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024