10 月 . 17, 2024 16:10 Back to list

Knife Gate Valve Cost Analysis and Market Pricing Trends

Understanding Knife Gate Valve Pricing Factors and Insights

In industrial applications, the choice of valve can have a significant impact on efficiency, safety, and costs. One type of valve that has gained popularity in various sectors, including wastewater treatment, mining, and process industries, is the knife gate valve. Known for its straightforward design and effectiveness in controlling flow in large pipelines, understanding the pricing of knife gate valves is crucial for procurement professionals and engineers alike.

What is a Knife Gate Valve?

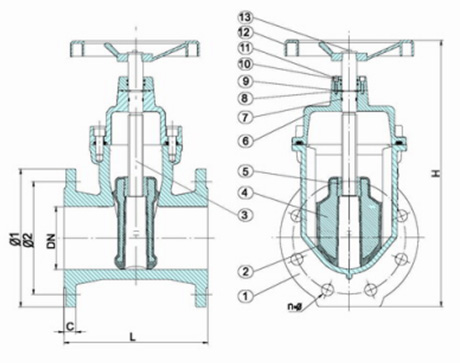

A knife gate valve is a type of gate valve that features a sharp-edged blade (or knife) that slides down through the media to cut and control the flow. This design allows for effective isolation and control of fluids, slurries, and materials that may be viscous or contain solid particles. The valve's unique construction makes it ideal for high-pressure applications and provides excellent sealing capabilities, which are essential for preventing leaks and ensuring operational integrity.

Factors Influencing Knife Gate Valve Pricing

Several factors influence the pricing of knife gate valves, leading to a range of costs across different types and brands. Below are the primary factors that impact their prices

1. Material of Construction The materials used in manufacturing knife gate valves can significantly affect their cost. Common materials include stainless steel, carbon steel, cast iron, and more specialized alloys for corrosive or high-temperature environments. Higher-grade materials typically increase the valve's durability but also raise the price.

2. Size and Dimensions Knife gate valves come in various sizes, from small valves suitable for minor applications to large-scale valves designed for heavy-duty industrial use. Generally, larger valves require more material and more robust construction, which can drive up the price.

3. Pressure Class Knife gate valves are rated for different pressure classes, such as low, medium, and high pressure. Valves designed to withstand higher pressures tend to be more expensive due to the need for reinforced materials and additional design considerations.

knife gate valve price

4. Design Features Advanced design features, such as automated actuation (electric or pneumatic), enhanced sealing mechanisms, or unique installation fittings, can increase the complexity and cost of the valve. Valves with additional functionalities usually command higher prices.

5. Brand and Manufacturer The reputation and reliability of the manufacturer can also play a significant role in pricing. Established brands often charge a premium due to their track record of quality and performance. However, less prominent manufacturers may offer competitive pricing to gain market share without compromising quality.

6. Market Demand and Supply The overall market condition can avidly influence pricing. In times of high demand or when supply chain issues arise, prices may increase. Conversely, during periods of economic downturn or reduced industrial activity, prices may decrease.

7. Customization and Special Orders Custom orders for specific applications can also impact the price. If a valve is required to meet particular specifications or industry standards, this might lead to additional costs, as manufacturers tailor the products accordingly.

Typical Price Range

The cost of knife gate valves can vary widely based on the factors mentioned above. On average, the price for smaller valves may start at around $100 to $300, while larger, heavy-duty options can range from $500 to over $2,000 or more. Specialized valves with advanced features or made from high-grade materials can cost even higher, sometimes exceeding $5,000.

Conclusion

In conclusion, understanding the pricing of knife gate valves requires a comprehensive look at various influencing factors, including material, size, pressure class, and design specifications. As industries continue to evolve, the demand for reliable and efficient valve solutions rises, making it imperative for buyers to be informed about their options. By considering the various aspects that contribute to pricing, procurement professionals can make more informed decisions, ensuring they acquire the right knife gate valves for their operational needs without compromising on quality or performance. Whether for a minor project or a large-scale operation, investing time in understanding valve pricing can lead to better outcomes and cost savings in the long run.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024