10 月 . 02, 2024 15:03 Back to list

knife gate valve manufacturers

Understanding Knife Gate Valve Manufacturers An Insight into the Industry

Knife gate valves are essential components in various industrial applications, particularly in the handling of slurries, solids, and viscous fluids. These valves are designed to control the flow of media in pipelines, offering reliable shut-off capabilities, which makes them a preferred choice in industries such as mining, wastewater treatment, and pulp and paper. In this article, we delve into the key aspects of knife gate valve manufacturers, their product offerings, and industry significance.

What is a Knife Gate Valve?

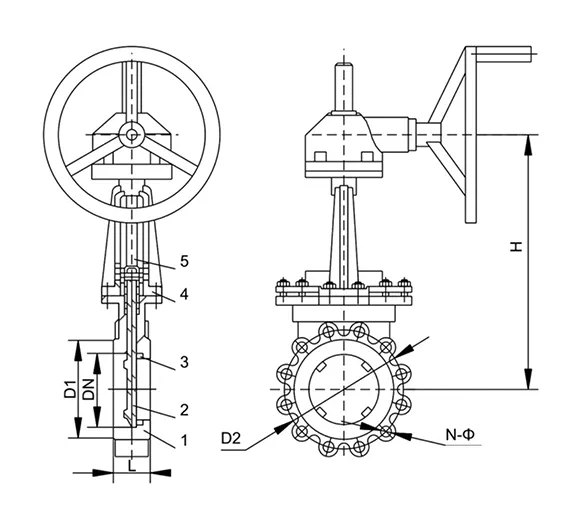

A knife gate valve comprises a flat-bladed gate that can be raised or lowered to control fluid flow. The design allows for effective sealing even in the presence of solid particles, making it ideal for applications where media composition may be abrasive or contain suspended solids. The unique feature of a knife gate valve is its ability to ‘cut through’ materials, providing a tight shut-off when fully closed. This mechanism differentiates it from other valve types and enhances its functionality in challenging operational environments.

The Role of Manufacturers

Manufacturers of knife gate valves play an integral role in the supply chain of industrial equipment. These companies engage in the design, production, and distribution of valves tailored to meet specific operational requirements. High-quality manufacturing processes ensure that the valves can withstand harsh conditions while maintaining optimal performance. Several factors influence manufacturing capabilities, including material selection, engineering design, testing procedures, and adherence to industry standards.

Key Considerations When Choosing a Manufacturer

1. Quality Assurance Look for manufacturers who adhere to recognized quality standards such as ISO 9001. This certification ensures that the manufacturer has a robust quality management system in place, which results in consistent product quality.

knife gate valve manufacturers

2. Material Options Different applications require various materials for optimal performance. Leading manufacturers offer a range of options, including stainless steel, carbon steel, and other alloys, ensuring that the valves can handle specific chemical and temperature conditions.

3. Customization Many knife gate valve manufacturers offer customization options to meet unique requirements. This flexibility includes modifications to size, pressure ratings, and end connections, catering to the diverse needs of different industries.

4. Technical Support and Expertise A reliable manufacturer should provide comprehensive technical support, including guidance on valve selection, installation, and maintenance. Their expertise can assist customers in optimizing their fluid management systems.

5. Reputation and Experience Consider manufacturers with a strong reputation and extensive experience in the valve industry. Established companies are more likely to have tested their products under various conditions and can provide proven solutions for specific applications.

The Future of Knife Gate Valves

As industries continue to evolve, so do the demands placed on knife gate valves. Manufacturers are increasingly focusing on innovation, incorporating advanced technologies and materials to enhance performance and durability. Sustainable practices are also becoming a focal point, with manufacturers striving to reduce their environmental footprint through energy-efficient production methods and recyclable materials.

In conclusion, knife gate valve manufacturers play a pivotal role in providing reliable flow control solutions for various industries. By considering factors like quality, material options, customization, and technical support, businesses can partner with the right manufacturers to ensure efficient operations and long-term success. As technology and industry standards advance, the evolution of knife gate valves promises to meet the challenges of modern engineering, ultimately benefiting the sectors that rely on these essential components.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024