9 月 . 22, 2024 04:38 Back to list

industrial water valve

Understanding Industrial Water Valves Essential Components for Effective Water Management

Industrial water valves play a crucial role in the management and distribution of water in various industrial settings. From manufacturing plants to wastewater treatment facilities, these valves are vital for controlling the flow, pressure, and temperature of water, ensuring efficient operations and adherence to safety standards.

Types of Industrial Water Valves

There are several types of water valves used in industrial applications, each serving specific functions. The most common types include

1. Gate Valves These are primarily used to start or stop the flow of water. They operate with a wedge-shaped disc that moves up and down, allowing or blocking water flow. Gate valves are ideal for applications requiring minimal pressure drop and are typically used in larger pipelines.

2. Globe Valves Designed for throttling flow, globe valves feature a spherical body that allows for precise control of water flow. They are particularly useful in applications where flow rate regulation is necessary, such as in cooling systems.

3. Ball Valves Known for their excellent sealing capabilities, ball valves feature a spherical disc that controls the flow. They are easy to operate and provide quick shut-off, making them suitable for applications requiring fast response times.

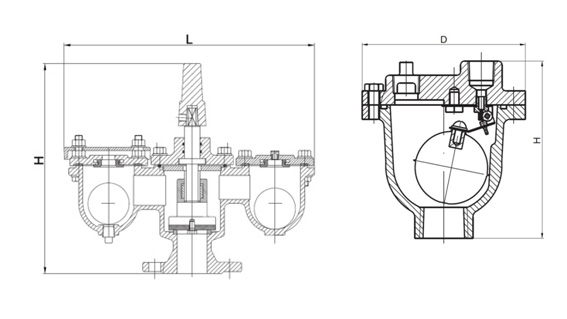

4. Check Valves These valves permit water flow in one direction only, preventing backflow that can lead to contamination and damage to the system. Check valves are essential for maintaining the integrity of water supply lines.

5. Butterfly Valves Utilizing a rotating disc to regulate flow, butterfly valves are compact and lightweight, making them ideal for large-scale industrial applications. They allow for quick operation and are suitable for both on-off and throttling service.

Applications in Industry

Industrial water valves find applications in various sectors, including

industrial water valve

- Manufacturing In production facilities, water valves control the flow of coolant in machinery, maintain temperatures, and manage waste. Proper valve selection can enhance equipment efficiency and longevity.

- Water Treatment Valves play a critical role in controlling the flow of water through filtration systems, chemical dosing units, and disinfection processes. They help ensure compliance with environmental regulations and deliver safe, treated water.

- Power Generation In power plants, water valves manage cooling systems, steam generation, and wastewater disposal. Their reliable operation is essential for maintaining energy production efficiency.

- Agriculture In irrigation systems, water valves help manage the distribution of water to crops, optimizing resource use and enhancing yield

.Maintenance and Best Practices

To ensure optimal performance and longevity, industrial water valves require regular maintenance. Key best practices include

- Regular Inspections Check for leaks, wear, and proper operation during routine maintenance schedules.

- Cleaning Accumulation of debris can hinder valve performance, so ensuring valves are clean is crucial.

- Lubrication Moving parts should be properly lubricated to prevent corrosion and facilitate smooth operation.

In conclusion, industrial water valves are essential for effective water management across various industries. Understanding their types, applications, and maintenance requirements is key to optimizing their use and ensuring the efficient operation of water systems. As industries evolve and demand for efficient water management increases, the importance of quality industrial water valves cannot be overstated.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024