1 月 . 06, 2025 11:10 Back to list

industrial valve

Industrial valves, crucial components in numerous industries, play an indispensable role in regulating the flow of liquids, gases, or slurries. Their superior performance and reliability hinge on meticulous engineering and material selection. Drawing from decades of experience in industrial engineering, I offer insights into the critical features and advantages of high-quality industrial valves, enhancing their appeal and utility in diverse applications.

Among the key attributes of industrial valves is their robust construction. Crafted from materials such as stainless steel, brass, or titanium, these valves are designed to withstand extreme conditions, including high pressure, temperature fluctuations, and corrosive environments. This durability translates into longer lifespan and reduced maintenance frequency—an expertise-driven insight important to operations where reliability is paramount.

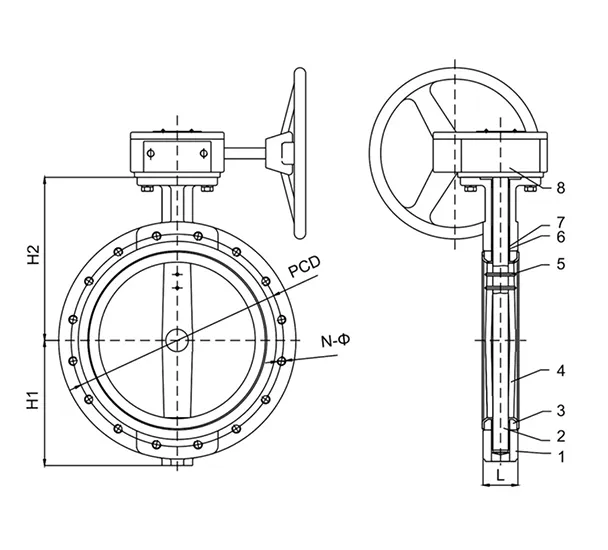

Moreover, the variety of industrial valves available—ball, gate, globe, butterfly, and check valves, among others—each serve specific functions tailored to different industrial requirements. For instance, ball valves provide excellent shut-off capabilities, ideal for systems requiring tight sealing under high pressure. On the other hand, butterfly valves, known for their light weight and cost-effectiveness, are suitable for larger pipes and applications requiring quick shutoff.

Safety and compliance with standards are fundamental to the trustworthiness of industrial valve solutions. Adherence to international standards such as ASME, API, and ISO not only ensures safe operation but also enhances the credibility of manufacturers in competitive markets. Experience shows that regular audits and certifications are vital practices within reputable manufacturing operations, fostering trust and reliability among clients seeking quality assurance.

industrial valve

Innovative features such as automation and intelligent monitoring systems are becoming increasingly prevalent in response to technological advancements. The integration of smart technologies allows for real-time data monitoring, predictive maintenance, and remote control, setting new benchmarks in operational efficiency. Notably, industries adopting these cutting-edge solutions report enhanced operational efficiency and cost savings—evidence of authoritative expertise in action.

Furthermore, customization options are imperative for meeting specific industry demands. Whether it’s high-pressure scenarios, sanitary applications in food and pharmaceuticals, or specialized needs in nuclear power generation, expert manufacturers offer bespoke solutions that cater to the intricate requirements of each sector. Customer testimonials frequently highlight the bespoke engineering practices and responsive support services as hallmarks of reliable industrial valve suppliers.

Finally, the environmental impact of industrial valves is a growing concern, emphasizing the need for sustainable practices. Valves with enhanced sealing technology reduce emissions and leaks, thereby supporting sustainability goals. Expertise in design and materials science, combined with a commitment to environmental stewardship, enhances a company’s reputation and aligns with the evolving regulatory landscape.

In conclusion, the hallmarks of superior industrial valves—durability, safety, innovation, customization, and sustainability—reflect a culmination of extensive experience, professional expertise, and a commitment to trustworthiness. As industries continue to evolve, the strategic integration of these elements promises not only improved operational efficiency but also a competitive edge in the global market.

Share

-

Understanding the Differences Between Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Efficiency of Wafer Type Butterfly Valve and Lugged Butterfly ValveNewsOct.25,2024

-

The Ultimate Guide to Industrial Swing Check Valve: Performance, Installation, and MaintenanceNewsOct.25,2024

-

Superior Performance with Industrial Swing Check Valve: The Essential Valve for Any SystemNewsOct.25,2024

-

Industrial Swing Check Valve: The Ideal Solution for Flow ControlNewsOct.25,2024

-

You Need to Know About Industrial Swing Check Valve: Functionality, Scope, and PerformanceNewsOct.25,2024